- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

Ceramics greatly differ in their basic composition, and their properties also vary greatly due to differences in bonding. Classification of ceramics based on their specific applications and composition are the two most important ways among many ceramic classification methods.

Based on their composition, ceramics are classified as:

Oxides,

Carbides,

Nitrides,

Sulfides,

Fluorides, etc.

Further reading: Classification of Ceramic Materials Based on Composition

The other important classification of ceramics is based on their application, such as:

Glasses,

Clay products,

Refractories,

Abrasives,

Cements,

China Special Ceramic Parts.

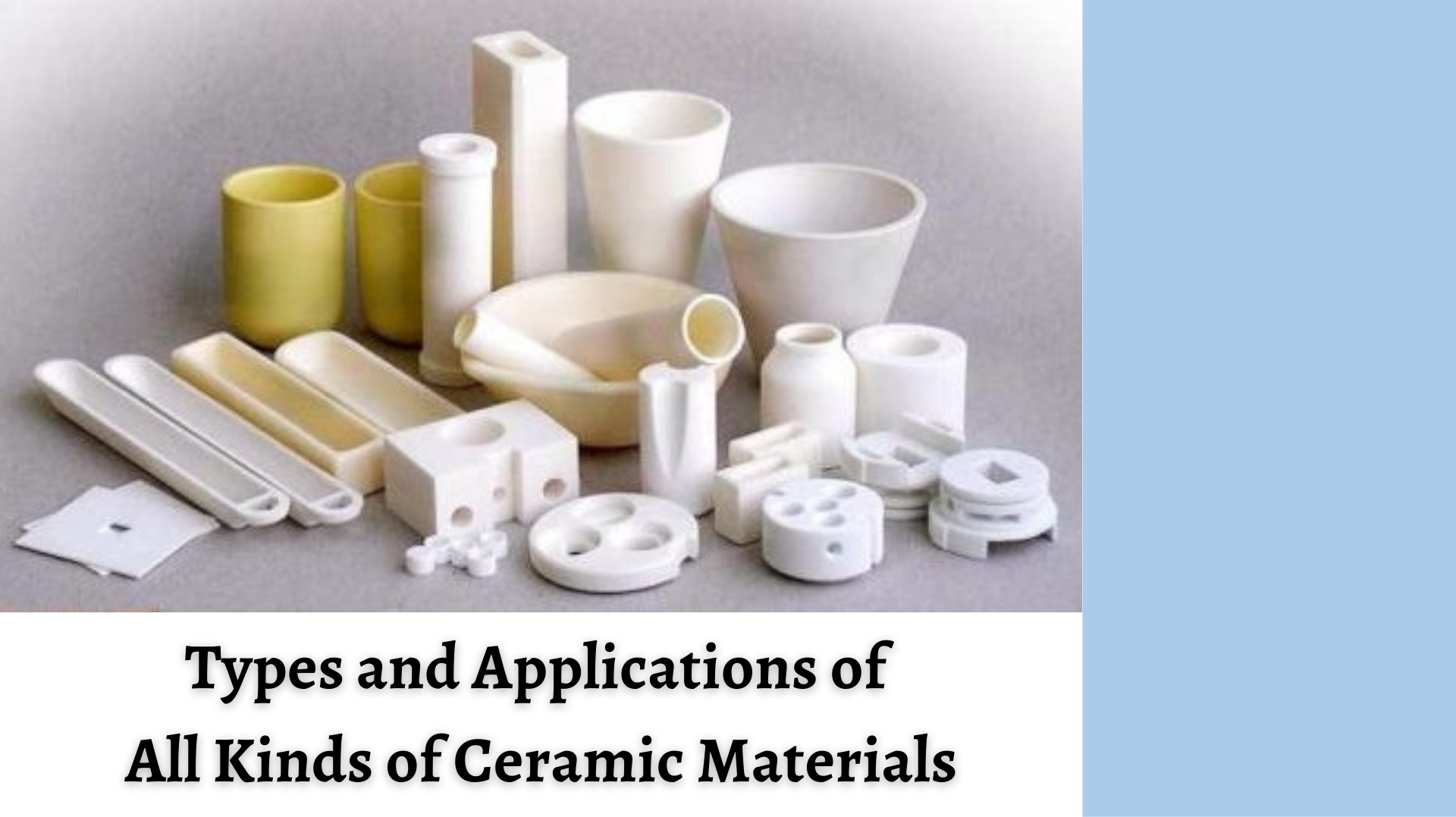

In general, ceramic materials used for engineering applications can be divided into two groups: traditional ceramics, and China Special Ceramic Parts. Typically, traditional ceramics are made from three basic components: clay, silica (flint) and feldspar. For example, bricks, tiles and porcelain articles. However, China Special Ceramic Parts, Inc. consist of highly pure compounds of aluminum oxide (Al2O3), silicon carbide (SiC) and silicon nitride (Si3N4).

Glasses are a familiar group of ceramics – containers, windows, mirrors, lenses, etc. They are non-crystalline silicates containing other oxides, usually CaO, Na2O, K2O and Al2O3 which influence the glass properties and its color. A typical property of glasses that is important in engineering applications is its response to heating. There is no definite temperature at which the liquid transforms into a solid as with crystalline materials. A specific temperature, known as glass transition temperature or fictive temperature is defined based on viscosity above which material is named as supercooled liquid or liquid, and below it is termed as glass.

Types of Ceramics-Glasses

Clay is one of the most widely used ceramic raw materials. It is found in great abundance and popular because of the ease with which products are made. Clay products are mainly two kinds – structural products (bricks, tiles, sewer pipes) and whitewares (porcelain, chinaware, pottery, etc.).

Types of Ceramics-Clay

These are described by their capacity to withstand high temperatures without melting or decomposing; and their inertness in severe environments. Thermal insulation is also an important function of refractories.

Abrasive ceramics are used to grind, wear, or cut away other material. Thus the prime requisite for this group of materials is hardness or wear resistance in addition to high toughness. As they may also be exposed to high temperatures, they need to exhibit some refractoriness. Diamond, silicon carbide, tungsten carbide, silica sand, aluminum oxide/corundum are some typical examples of abrasive ceramic materials.

Cement, plaster of paris and lime come under this group of ceramics. The characteristic property of these materials is that when they are mixed with water, they form slurry which sets subsequently and hardens finally. Thus it is possible to form virtually any shape. They are also used as bonding phase, for example between construction bricks.

China Special Ceramic Parts, Inc. are newly developed and manufactured in a limited range for specific applications. Usually, their electrical, magnetic and optical properties and combination of properties are exploited. Typical applications: heat engines, ceramic armors, electronic packaging, etc. Some typical ceramics and respective applications are as follows:

Types of Ceramics-China Special Ceramic Parts

Aluminum oxide / Alumina (Al2O3): it is one of the most commonly used ceramic materials. Alumina is used in many applications such as to contain molten metal, where the material is operated at very high temperatures under heavy loads, as insulators in spark plugs, and in some unique applications such as dental and medical use. Chromium doped alumina is used for making lasers.

Aluminum nitride (AlN): because of its typical properties such as good electrical insulation but high thermal conductivity, aluminum nitride is used in many electronic applications such as in electrical circuits operating at a high frequency. It is also suitable for integrated circuits. Other electronic ceramics include – barium titanate (BaTiO3) and Cordierite (2MgO-2Al2O3-5SiO2).

Diamond (C): it is the hardest material known to available in nature. It has many applications such as industrial abrasives, cutting tools, abrasion-resistant coatings, etc. it is, of course, also used in jewelry.

Lead zirconium titanate (PZT): it is the most widely used piezoelectric material, and is used as gas igniters, ultrasound imaging, in underwater detectors.

Silica (SiO2): is an essential ingredient in many engineering ceramics, thus is the most widely used ceramic material. Silica-based materials are used in thermal insulation, abrasives, laboratory glassware, etc. it also found application in communications media as integral part of optical fibers. Fine particles of silica are used in tires, paints, etc.

Silicon carbide (SiC): it is known as one of the best ceramic material for very high-temperature applications. Silicon carbide is used as coatings on other materials for protection from extreme temperatures. It is also used as the abrasive material. It is used as a reinforcement in many metallic and ceramic-based composites. It is a semiconductor and often used in high-temperature electronics. Silicon nitride (Si3N4) has properties similar to those of SiC but is somewhat lower, and found applications in such as automotive and gas turbine engines.

Titanium oxide (TiO2): it is mostly found as a pigment in paints. It also forms part of certain glass-ceramics. It is used to making other ceramics like BaTiO3.

Titanium boride (TiB2): it exhibits great toughness properties and hence found applications in armor production. It is also a good conductor of both electricity and heat.

Uranium oxide (UO2): it is mainly used as nuclear reactor fuel. It has exceptional dimensional stability because its crystal structure can accommodate the products of the fission process.

Yttrium aluminum garnet (YAG, Y3Al5O12): it has main application in lasers (Nd-YAG lasers).

Zirconia (ZrO2): it is also used in producing many other ceramic materials. Zirconia is also used in making oxygen gas sensors, as an additive in many electronic ceramics. Its single crystals are part of jewelry.

Copyright (c) 1994-2022 China Special Ceramic Parts, Inc. owned by Oceania International LLC, All Rights Reserved.

THANKS FOR THIS USEFUL ARTICLE ON CERAMICS , VERY INFORMATIVE

Thanks for this great knowledge, very educative.

Very deep detail about ceramics! Nice research