- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

Zirconia ceramic, also known as zirconium oxide (ZrO2), is a white crystalline oxide of zirconium. Its most naturally occurring form is the mineral baddeleyite with a monoclinic crystalline structure.

Zirconium oxide ceramics have the highest toughness and strength at room temperature of all the China Special Ceramic Parts, Inc.. It also has a high thermal expansion, low thermal conductivity, and high resistance to corrosion. Its unique resistance to crack propagation and high thermal expansion make it an excellent material for joining ceramics and metals such as steel.

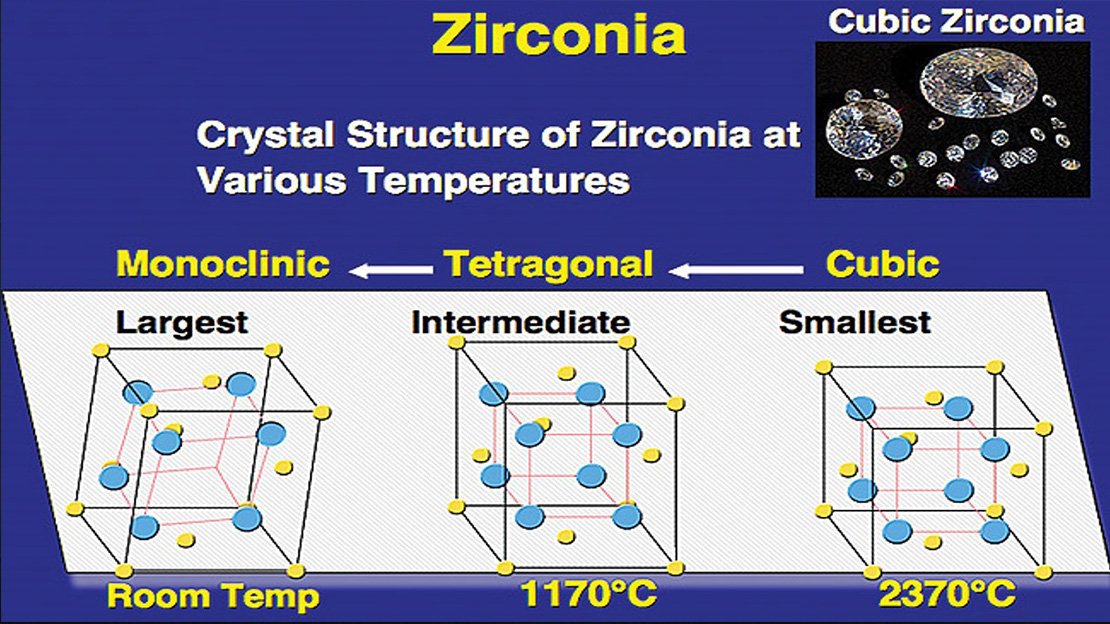

There are three types of crystal structures of zirconia ceramics: cubic crystal, tetragonal and monoclinic. Pure zirconia is monoclinic (m), under ambient conditions. With increasing temperature, the material transforms to a tetragonal crystal structure (t) at ~1170 °C and then to a cubic crystal structure (c), followed by a fluorite structure at ~2370 °C with melting at 2716 °C.

| Compound Formula | ZrO2 |

| Molecular Weight | 123.22 |

| Appearance | White |

| Melting Point | 2,715° C (4,919° F) |

| Boiling Point | 4,300° C (7,772° F) |

| Density | >5.68 g/cm3 |

| Water absorption | <0> |

| Hardness | 1350 HV |

| Hot expansion coefficient | 9.5×10-6 /°C |

| Fracture toughness | 8.0 MPa m 1/2 |

| CAS#: 1314-23-4, Not Hazardous, F.W. 123.22, m.p. 2700 °C, b.p. ~5000 °C, Spec. Gravity 5.89 gm/cm3 | |||

| White Powder. All grades are manufactured by the calcination of chemically co-precipitated or re-crystallization intermediates. | |||

| Item No. | Description | Purity | Lot Size |

| OX40-3N | Zirconia Fine Powder D50= -325 mesh |

99.9 % Na2O < 0.01%; Fe2O3 < 0.003%; SiO2 < 0.05% |

1 MT 10 MT Customize |

| OX40-3NE | Zirconia White Fine Powder (by Precipitation) D50= 1~3 um Surface Area: > 5 m2/g |

99.9 % Na2O < 0.01%; Fe2O3 < 0.001%; SiO2 < 0.015% |

1 MT 10 MT Customize |

| OX40-3NF | Zirconia White Fine Powder (by Precipitation) D50= < 1.0 um Surface Area: > 8 m2/g |

99.9 % Na2O < 0.01%; Fe2O3 < 0.001%; SiO2 < 0.015% |

1 MT 10 MT Customize |

| OX40-3N5E | Zirconia White Fine Powder (by Precipitation) D50= 1~3 um Surface Area: > 5 m2/g |

99.95 % Na2O < 0.005%; Fe2O3 < 0.001%; SiO2 < 0.01% |

1 MT 10 MT Customize |

| OX40-3N5F | Zirconia White Fine Powder (by Precipitation) D50= 0.5~ 1.0 um Surface Area: > 15 m2/g |

99.95 % Na2O < 0.005%; Fe2O3 < 0.001%; SiO2 < 0.01% |

1 MT 10 MT Customize |

| OX40-3N5G | Zirconia White Powder (by Precipitation) -200 mesh or -325 mesh |

99.95 % Na2O < 0.005%; Fe2O3 < 0.0005%; SiO2 < 0.01% |

1 MT 10 MT Customize |

| White Powder. All grades here are manufactured by the calcination of chemically co-precipitated intermediates. | |||

| Item No. | Description | Purity | Lot Size |

| PSZ-5.2Y | Yttria (3 mol%) Stabilized Zirconia D50 < 0.5 um; Specific Surface Area > 20 m2/gm |

Zr(Hf)O2 94.5%; Y2O3: 5.2 ± 0.2 % |

100 kg 1,000 kg Customize |

| PSZ-5.2YB | Yttria (3 mol%) Stabilized Zirconia, Spray-dried, coated with PVA binder and ready to press. Granule size:70 -100 um; |

Zr(Hf)O2 94.5%; Y2O3: 5.2 ± 0.2 % |

100 kg 1,000 kg Customize |

| PSZ-5.5Y | Yttria (3 mol%) Stabilized Zirconia D50= 0.5 – 1.0 um; Specific Surface Area > 15 m 2/gm |

Zr(Hf)O2 93.5%; Y2O3: 5.5 ± 0.2 % |

100 kg 1,000 kg Customize |

| PSZ-5.5YS | Yttria (3 mol%) Stabilized Zirconia D50= 0.5-1 um; Specific Surface Area = 7 – 9 m 2/gm. Best for tape casting, slip casting and injection molding techniques |

Zr(Hf)O2 93.5%; Y2O3: 5.5 ± 0.2 % |

100 kg 1,000 kg Customize |

| PSZ-13.5Y | Yttria (8 mol%) Fully Stabilized Zirconia D50 = 0.5 – 1.0 um; Specific Surface Area > 15 m2/gm. Best for pressing techniques. |

Zr(Hf)O2 85.5%; Y2O3: 13.5 ± 0.2 % |

100 kg 1,000 kg Customize |

| PSZ-13.5YS | Yttria (8 mol%) Fully Stabilized Zirconia D50 = 0.5 – 1.0 um; Specific Surface Area 7 – 9 m2/gm. Best for tape casting, slip casting and injection molding techniques. |

Zr(Hf)O2 85.5%; Y2O3: 13.5 ± 0.2 % |

100 kg 1,000 kg Customize |

– Production of hard ceramics.

– Protective coating on particles of titanium dioxide pigments.

– Refractory material, in insulation, abrasives and enamels.

– Stabilized ZrO2 is used in oxygen sensors and fuel cell membranes.

– Solid electrolyte in electrochromic devices.

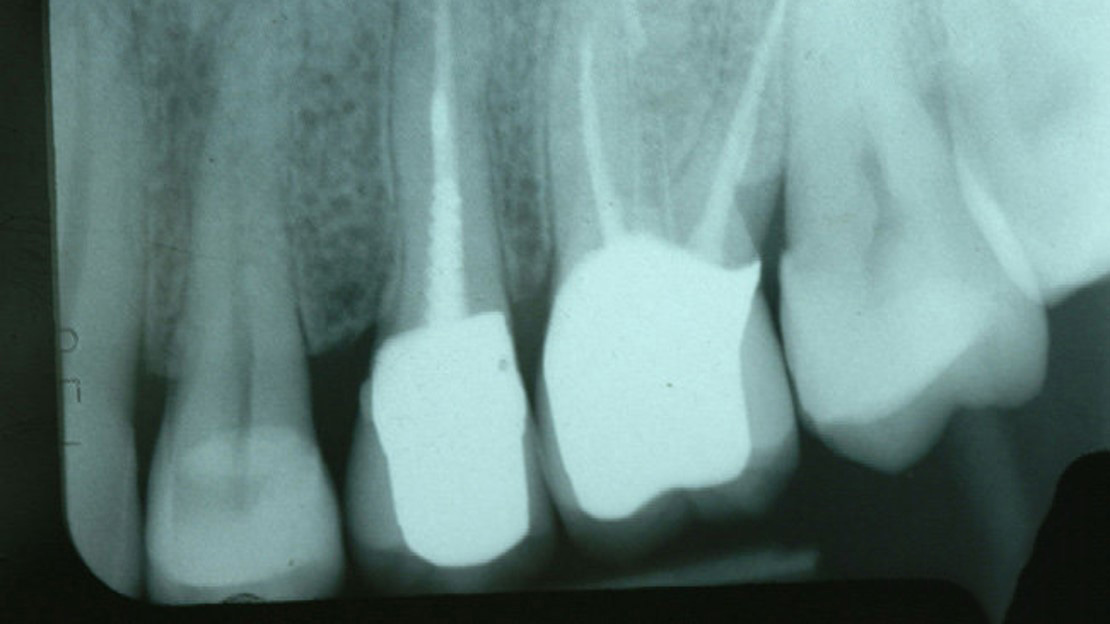

– Dental crowns, zirconia crowns.

China Special Ceramic Parts, Inc. (CSCPI) is a leading supplier of zirconia ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us for any questions about ZrO2 or other ceramic materials that are not listed on the website.