- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

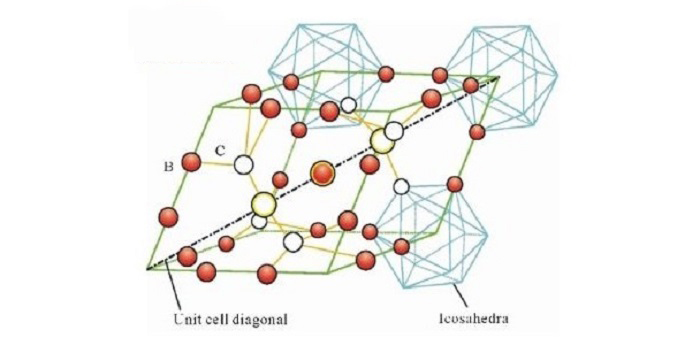

Boron Carbide, or B4C, is an extremely hard ceramic material discovered in 1899. With a Mohs hardness between 9 and 10, boron carbide is one of the hardest synthetic substances known, being exceeded only by cubic boron nitride (CBN) and diamond. Besides, it has good chemical inertness and a high neutron absorption cross-section. Thus, it is a suitable material for many high-performance applications, such as anti-oxidant in carbon-bonded refractory mixes, reactor control rods and neutron-absorbing shielding in nuclear applications

Boron Carbide Crystal Structure

* Low thermal conductivity

* Susceptible to thermal shock failure

* Outstanding hardness

* Extremely brittle

* Semiconductor

* Good thermal-neutron capture

| CAS#: 12069-32-8, Not Hazardous | |||

| Powder, F.W. 55.26, m.p. 2350 °C, Spec. Gravity 2.52 gm/cm3 | |||

| Item No. | Description | Purity | Lot Size |

| CB05-100M | Boron Carbide Powder Particle Size: 100 mesh |

Total B > 78 %, Total C > 19% B2O3 < 0.15%, Free B < 0.3%, Free C < 2.5% |

100 kg 500 kg 1,000 kg Customize |

| CB05-325M | Boron Carbide Powder Particle Size: 325 mesh |

Total B > 78 %, Total C > 19% B2O3 < 0.15%, Free B < 0.3%, Free C < 2.5% |

100 kg 500 kg 1,000 kg Customize |

| CB05-1000 | Boron Carbide Powder Particle Size:1000 Grit |

Total B > 78 %, Total C > 19% B4C > 95% B2O3 < 0.15%, Fe < 0.2% |

100 kg 500 kg 1,000 kg Customize |

| CB05-1200 | Boron Carbide Powder Particle Size:1200 Grit |

Total B > 78 %, Total C > 19% B4C > 95% B2O3 < 0.15%, Fe < 0.2% |

100 kg 500 kg 1,000 kg Customize |

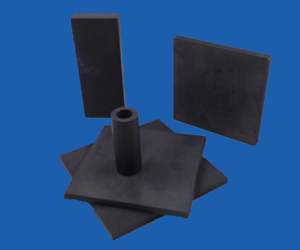

Boron carbide ceramics are applied widely in industries as wearing resistant materials, and abrasives. As an abrasive, it is used in powdered form in the lapping (fine abrading) of metal and ceramic products, though its low oxidation temperature of 400–500° C (750–930° F) makes it unable to withstand the heat of grinding hardened tool steels.

Because of its hardness, together with its very low density, it has found application as a reinforcing agent for aluminum in military armor and high-performance bicycles, and its wear resistance has caused it to be employed in sandblasting nozzles and pump seals.

Its ability to absorb neutrons without forming long-lived radionuclides makes it attractive as an absorbent for neutron radiation arising in nuclear power plants and from anti-personnel neutron bombs. Nuclear applications of boron carbide include shielding, control rod and shut down pellets. Within control rods, boron carbide is often powdered, to increase its surface area.

China Special Ceramic Parts, Inc. (CSCPI) is a leading supplier of boron carbide ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us for any questions about B4C or other ceramic materials that are not listed on the website.