- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

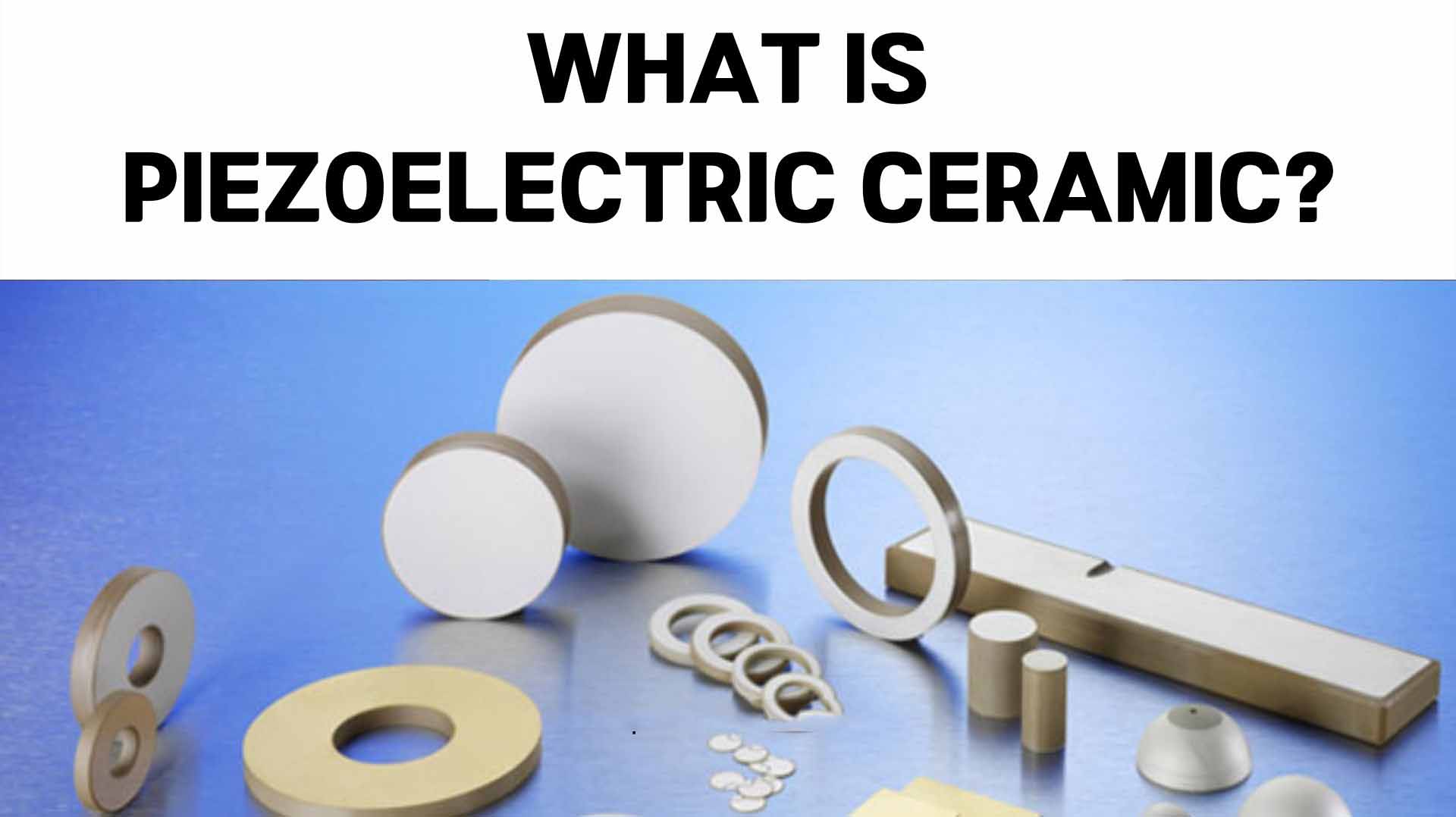

Piezoelectric ceramic is the general designation of ferroelectric ceramics with a piezoelectric effect through the polarization treatment of polycrystals made by mixing oxide (zirconia, lead oxide, titanium oxide, etc.) with high-temperature sintering and solid reaction. With good mechanical and stable piezoelectric properties, piezoelectric ceramics have been widely used in sensors, the ultrasonic transducer, microdisplacement device, and other electronic components, etc. as an important force, heat, electricity, light-sensitive functional material.

With the continuous research and improvement of materials technology, and the rapid development of electronic, information, aerospace and other high-tech fields, the production technology and application development of piezoelectric ceramic with high intelligent materials has become a hot topic.

In 1880, the Curie brothers first discovered the piezoelectric effect of tourmaline and began the history of piezoelectricity.

The Curie brothers

In 1894, Voigt pointed out that it was possible to have a piezoelectric effect on the crystals of the twenty-point groups of the asymmetrical center. Quartz is a representative of piezoelectric crystals and it has been applied. During World War I, Curie’s successor Langevin was the first to use the piezoelectric effect of quartz to make an underwater ultrasonic detector, which was used to detect submarines, thus opening the page of piezoelectric applications.

The development of piezoelectric materials and their applications was attributed to the discovery of BaTiO3 ceramics in World War II. In 1947, Roberts applied high pressure for polarization treatment on BaTiO3 ceramics and obtained the voltage of piezoelectric ceramics. Subsequently, Japan developed the application of BaTiO3 piezoelectric ceramic actively to make ultrasonic transducers, high-frequency transducers, pressure sensors, filters, resonators and other piezoelectric devices. The study continued until the mid-1950s.

Since the late eighties, people have developed ceramic materials for ferroelectric ceramics. In this way, the single-crystal materials of the iron and electric body were successfully developed, which laid a foundation for three-dimensional ultrasonic imaging. At present, new breakthroughs have been made in the application of nanotechnology to the fabrication of piezoelectric materials.

Currently, the world is developing lead-free piezoelectric ceramics to protect the environment and pursue health.

The dielectric properties of piezoelectric ceramics reflect the degree of response of the ceramic material to an external electric field.

The elastic coefficient of piezoelectric ceramics is a parameter that reflects the relationship between the deformation of the ceramics and the applied force.

The biggest characteristic of piezoelectric ceramics is piezoelectricity, including positive piezoelectricity and inverse piezoelectricity. Positive piezoelectricity refers to the relative displacement of positive and negative charge centers in some dielectrics under the action of external mechanical force, resulting in polarization, which leads to the appearance of bound charges with opposite signs on the surfaces of the dielectrics.

Piezoelectric ceramics can be used as sound transducers for pickups, microphones, headphones, buzzers, ultrasonic sounders, sonar, and ultrasonic flaw detectors for materials. Piezoelectric ceramics can generate vibrations of different frequencies through the control of electronic circuits, thereby emitting various sounds. For example, electronic music greeting cards convert AC audio signals into sound signals through the inverse piezoelectric effect.

In order to fight against tanks, an anti-tank gun was invented. The armor-piercing projectile it fired would explode immediately when it touched the tank, blowing the tank to pieces. This is because the warhead is equipped with piezoelectric ceramics, which can convert the strong mechanical force when they collide into an instantaneous high voltage, and explode a spark to detonate the explosive.

Piezoelectric ceramics for anti-tank weapons

This is a new type of electronic lighter used on gas stoves. Just press the ignition button, and the piezoelectric ceramics on the lighter can generate high voltage to form electric sparks and ignite the gas. Piezo lighters are not only easy to use, safe and reliable, but also have a long service life.

Piezoelectric ceramics for gas stoves

When the optical radiation generated by the nuclear explosion reaches a dangerous level, the goggles made of transparent piezoelectric ceramics will convert it into instantaneous high-voltage electricity, which can reduce the light intensity to only 1/10000 in 1/1000 s. And it can return to its original state after the explosion. The goggles have a simple structure, weigh only a few tens of grams, and are very convenient to carry when mounted on a nuclear-proof goggle helmet.

Thank you for reading our article and we hope it can help you to have a better understanding of piezoelectric ceramics. If you want to know more about ceramics, we would like to advise you to visit China Special Ceramic Parts, Inc. (CSCPI) for more information.

Copyright (c) 1994-2022 China Special Ceramic Parts, Inc. owned by Oceania International LLC, All Rights Reserved.