- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

A crucible is a container in which a substance may be melted or heated at very high temperatures. Modern-day crucibles can be made from any material that has a resistance to high temperatures. Pyrolytic boron nitride happens to be one of such materials. Crucibles usually come with a lid. However, the lids do not fit tightly to the crucibles. This is deliberate to allow gasses to escape from the crucibles during heating.

The first crucibles were found in Eastern Europe and some parts of Asia as far back as 6000 B.C. They were made mostly from clay. One tested and tried rule when picking a crucible is that the crucible should have a higher melting point than the substance to be melted in it.

In a laboratory, crucibles are usually used for experiments that require very high temperatures. Some of these experiments include quantitative gravimetric chemical analysis and ash content determination.

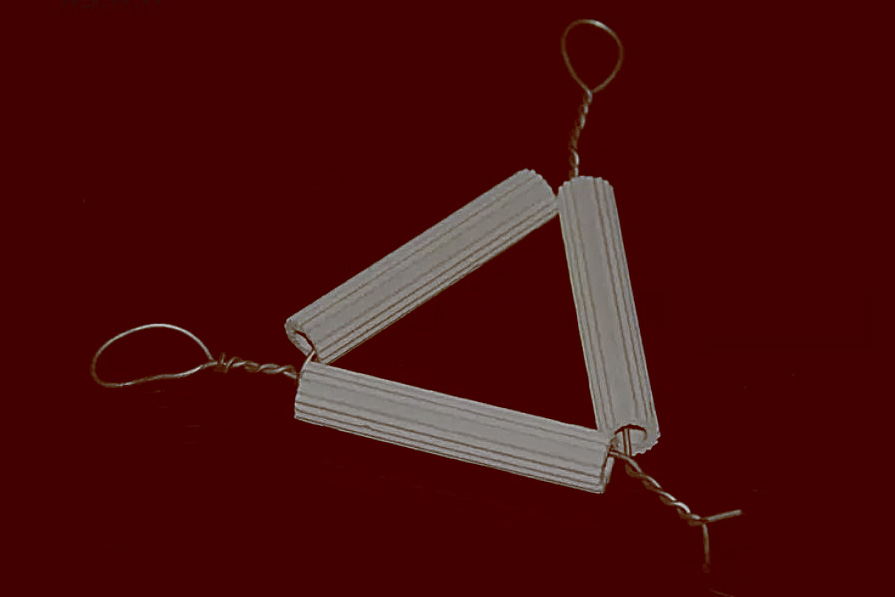

Some rules must be obeyed while using a crucible in a laboratory. This ensures that there is no accident. One of such rules is that the crucible is heated on an iron triangle. This rule exists because the bottom of a crucible is usually narrow.

In addition, after heating the crucible, it must be left on the iron triangle to cool. This is because transferring the crucible to another surface could damage the surface. It is important to use forceps while handling a crucible.

PBN crucibles are made from a ceramic material known as pyrolytic boron nitride. PBN crucibles have great mechanical strength and high purity. They are highly sought after in the semiconductor industry.

PBN crucibles have a lot of remarkable properties that make them ideal for laboratory use. For starters, they have resistance to high temperatures. This enables them to withstand the high temperatures that crucibles are often subjected to. In addition, PBN crucibles have high mechanical strength and high purity. This ensures that they are durable and efficient. PBN crucibles are also smooth. They have a non-porous surface. Another important property of PBN crucibles is that they can come in contact with acids, alkali, and salts without reacting. Thus, they are mostly chemically inert.

Here we explore some advantages of PBN crucibles that set them apart from other types of crucibles.

Further Reading: Lab Tips: How to Use and Clean Crucibles?

While pyrolytic boron nitride is an excellent crucible material, there are other remarkable crucible materials.

Graphite crucibles have a black solid appearance. They are used to melt metals at very high temperatures. They have a high-temperature resistance in addition to high acid and alkali resistance.

Porcelain crucibles are resistant to wear and tear. They are the most affordable crucibles for laboratory operations below 1473 K.

They are refractory vessels with high resistance to chemicals. Magnesium oxide crucibles are more chemically inert than alumina crucibles.

Alumina crucibles are made from aluminum oxide. However, the aluminum oxide used contains some impurities. Like most types of crucibles, they are chemically inert and resistant to high temperatures. Alumina crucibles function optimally until they reach a temperature of 2023 K.

Platinum is one of the oldest materials used in making crucibles. Platinum crucibles usually have a melting point of 1843 K. They are also chemically inert and are commonly used as analytical crucibles.

These crucibles have a melting point of up to 1323 K. Quartz crucibles may not have a melting point as high as some other crucibles but they are the crucibles of choice for some laboratory operations. They are used in analytical laboratory operations.

Zirconia crucibles have a low thermal expansion coefficient that makes them efficient. Not only are these crucibles efficient, but they are also affordable. Zirconia crucibles are also resistant to corrosion. They are used for melting superalloys and precious metals. These crucibles have a melting point of up to 2073 K.

PBN crucibles are high-quality crucibles. They have high purity, high mechanical strength, and high resistance to high temperatures. These properties of PBN crucibles make them versatile. For more information about ceramic materials, please visit https://www.speciaLceramicparts.com/.