- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

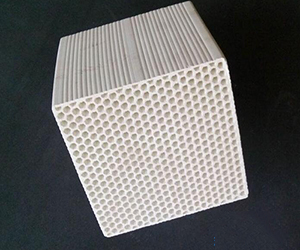

| Catalog No. | MC2692 |

|---|---|

| Color | Tan |

| Compositions | 3Al2O3oSiO2 |

| Working Temperature | ≤1500℃ |

| Hole Type | Round/Square |

Mullite Ceramic Honeycomb is made of mullite ceramic. Mullite is an excellent structural material due to its high-temperature stability, strength, and creep resistance. It has a low dielectric constant and high electrical insulation capabilities.

Mullite Ceramic Honeycomb is made of mullite ceramic. Mullite is an excellent structural material due to its high-temperature stability, strength, and creep resistance. It has a low dielectric constant and high electrical insulation capabilities.

Stanford Advanced Materials (SAM) is a trust-worthy supplier of Mullite Honeycomb Ceramic who has over two decades’ experience in supplying Mullite Ceramic Honeycomb of high quality at competitive prices.

|

Properties |

Units |

Test |

Value |

|

Physical |

|||

|

Chemical Formula |

– |

– |

3Al2O3-SiO2 |

|

Density, ρ |

g/cm3 |

ASTM C20 |

2.80 |

|

Color |

– |

– |

tan |

|

Crystal Structure |

– |

– |

orthorhombic |

|

Water Absorption |

% @R.T. |

ASTM C373 |

0.0 |

|

Hardness |

Moh's |

– |

8 |

|

Hardness |

knoop (kg/mm2) |

Knoop 100g |

1450 |

|

Mechanical |

|||

|

Compressive Strength |

MPa @ R.T. |

ASTM C773 |

551 |

|

Tensile Strength |

MPa @ R.T. |

ACMA Test #4 |

103.5 |

|

Modulus of Elasticity |

GPa |

ASTM C848 |

150 |

|

Flexural Strength (MOR) |

MPa @ R.T. |

ASTM F417 |

170 |

|

Poisson's Ratio, ν |

– |

ASTM C818 |

0.25 |

|

Fracture Toughness, KIc |

MPa x m1/2 |

Notched Beam Test |

2.0 |

|

Thermal |

|||

|

Max. Use Temperature |

oC |

No load cond. |

1700 |

|

Thermal Shock Resistance |

ΔT (oC) |

Quenching |

300 |

|

Thermal Conductivity |

W/m-K @ R.T. |

ASTM C408 |

3.5 |

|

Coefficient of Linear Thermal Expansion, αl |

um/m-oC (~25oC through ±1000oC) |

ASTM C372 |

5.3 |

|

Specific Heat, cp |

cal/g-oC @ R.T. |

ASTM C351 |

0.23 |

|

Electrical |

|||

|

Dielectric Constant |

1MHz @ R.T. |

ASTM D150 |

6.0 |

|

Dielectric Strength |

kV/mm |

ASTM D116 |

9.8 |

|

Electrical Resistivity |

Ω cm @ R.T. |

ASTM D1829 |

1013 |

|

SiO2% |

25-38 |

|

Al2O3% |

50-65 |

|

MgO% |

<1> |

|

K2O+Na2O3% |

<1> |

|

Fe2O3% |

<1> |

– Regenerator

– Refractory kiln furniture