- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

| Catalog No. | CM3298 |

| Material | Cordierite, Mullite, Corundum, Zirconia |

| Number of Cells / inch2 | 60-400 |

| Micro Cell (μm) | 2-3 |

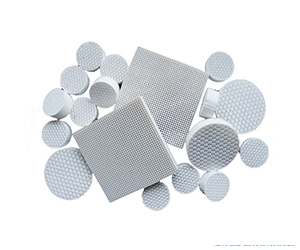

Honey Comb Ceramic Filter Plate is a new type of ceramic material widely used in metallurgical and foundry industries to filter metal melts. It has characteristics of heat shock resistance and high sintering temperature. It has natural chemical adsorption (affinity) ability for oxides. It adsorbs impurities in the molten metal (including particles smaller than the pore size) on the inner wall of the hole, and improves the filtering effect. The advanced extrusion production process makes the ceramic filter have a unique square or triangular design, which increases the contact area with the ceramic, improves the ability of the filter to absorb and capture small impurities, and has a better filtering effect than the non-extrusion filter. The molten metal flows smoothly, the pouring speed and continuity are improved; the casting waste rate is reduced. The mechanical properties of the castings are optimized and the service life is prolonged.

Honey Comb Ceramic Filter Plate is a new type of ceramic material widely used in metallurgical and foundry industries to filter metal melts. It has characteristics of heat shock resistance and high sintering temperature. It has natural chemical adsorption (affinity) ability for oxides. It adsorbs impurities in the molten metal (including particles smaller than the pore size) on the inner wall of the hole, and improves the filtering effect. The advanced extrusion production process makes the ceramic filter have a unique square or triangular design, which increases the contact area with the ceramic, improves the ability of the filter to absorb and capture small impurities, and has a better filtering effect than the non-extrusion filter. The molten metal flows smoothly, the pouring speed and continuity are improved; the casting waste rate is reduced. The mechanical properties of the castings are optimized and the service life is prolonged.

|

Material Item |

Cordierite | Cordierite-Mullite | Mullite | Corundum Mullite | Zirconia Mullite |

| Content of Al2O3 (%) | 35-37 | 40-50 | 50-60 | 68-73 | 68-73 |

| Cell Shape | Round/Square | ||||

| Number of Cells / Inch2 | 60-400 | ||||

| Micro Cell (μm) | 2-3 | ||||

| Thermal Expansion Coefficient (10^(-6)/K) | ≤1.8 | ≤3 | ≤5 | ≤5.5 | ≤5 |

| Softening Temperature (℃) | 1380 | 1500 | 1550 | 1700 | 1700 |

| Comprehensive Strength at Normal Temperature (MPa) | ≥12 | ≥15 | ≥15 | ≥15 | ≥15 |

* Casting alumina alloy

* Casting nodular iron and gray iron

* Casting stainless steel

Our Honey Comb Ceramic Filter Plates are carefully handled during storage and transportation to preserve the quality of our product in its original condition.