- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

Compared with normal boron nitride ceramic, pyrolytic boron nitride (PBN) has a much better purity level. PBN crucibles and other pyrolytic boron nitride products are synthesized on the mold by chemical vapor deposition (CVD) process, with BCl3 and NH3 at high temperature and low pressure. The PBN products are extremely pure, as the purity of vapor is easier to be controlled. Most PBN products made from the CVD process have a total impurity of less than 100 ppm, which means the purity is better than 99.99%. With such a high purity level, PBN crucibles are ideal products for semiconductor industries.

Similar to graphite, boron nitride has great strength at high temperatures. High purity PBN products have even better mechanical properties. As the solid material is formed by the CVD process, the density of the products could almost reach the theoretical value. PBN products provided by China Special Ceramic Parts, Inc. also have great thermal shock resistance. Plates of PBN could be heated to more than 2000 degrees and dropped into the water without getting broken.

Related: An overview of Pyrolytic Boron Nitride (PBN)

| Catalog No. | PBN0922 |

| Size | 5ml~5L |

| Material | PBN, Pyrolytic Boron Nitride |

| Standard | LEC, MBE, VGF |

| Purity | 99.99% |

| Product | Available size |

| Liquid Encapsulated Czochralski, PBN LEC crucibles | 50ml~5L |

| Molecular Beam Epitaxy, PBN MBE crucibles | 5ml~300ml |

| Vertical Gradient Freeze, PBN VGF crucibles | 0.2L~5L |

|

Item |

value |

Unit |

|

|

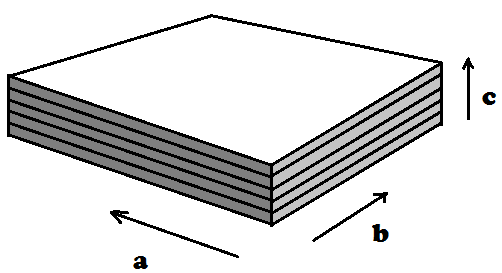

lattice constant |

a:2.504×10-10 c:6.692×10-10 |

μ m |

|

|

density |

2.0-2.19 |

g/cm3 |

|

|

resistivity |

3.11×1011 |

Ω·cm |

|

|

tensile strength(ab) |

153.86 |

N/mm2 |

|

|

bend strength |

c |

243.63 |

N/mm2 |

|

ab |

197.76 |

N/mm2 |

|

|

elastic modulus |

235690 |

N/mm2 |

|

|

thermo conductivity |

“a” direction “c” direction |

||

|

(200℃) |

60 2.60 |

W/m·k |

|

|

(900℃) |

43.70 2.80 |

W/m·k |

|

|

dielectric strength(at room temperature) |

56 |

KV/mm |

|

Pyrolytic Boron Nitride Crucible from China Special Ceramic Parts, Inc. can withstand high temperature in high vacuum environment, plus, it has excellent thermal conductivity, corrosion resistance and electrical resistance.

The PBN crucible product code is composed as follows:

Abbreviations and code:

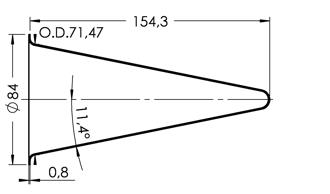

C conical-shaped crucibles

D double-wall crucibles

O lip

|

|

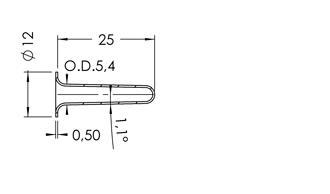

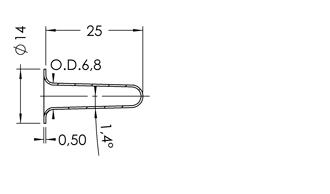

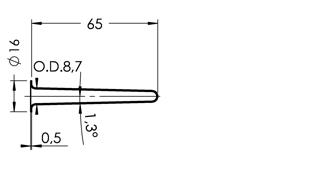

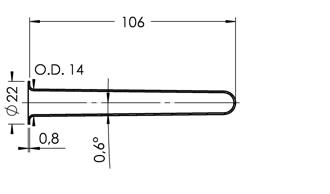

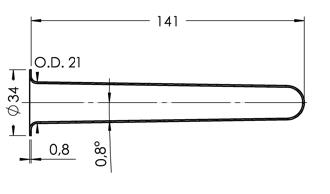

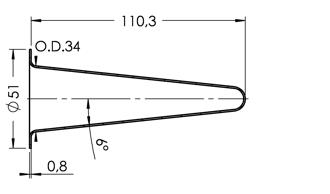

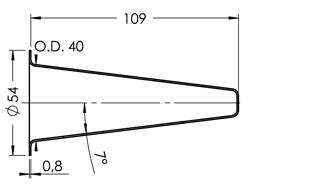

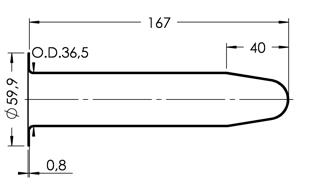

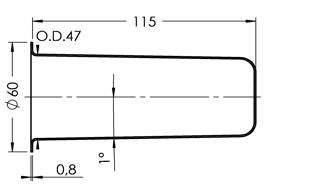

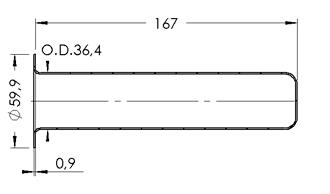

| Code: PBN 1-12 Capacity:1 cm^3 |

Code: PBN 1-14 Capacity:1 cm^3 |

|

|

| Code: PBN 1-20 Capacity: 1.5 cm^3 |

Code: PBN 2-16 Capacity: 2cm^3 |

|

|

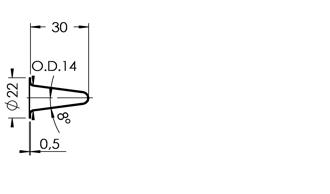

| Code: PBN C2-22 Capacity : 2 cm^3 |

Code: PBN 5-16 Capacity : 5 cm^3 |

|

|

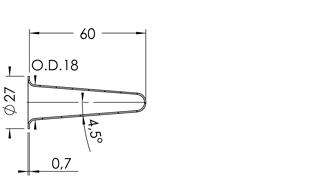

| Code: PBN C5-27 Capacity : 5 cm^3 |

Code: PBN C5-29 Capacity :5 cm^3 |

|

|

| Code: PBN C8-27 Capacity : 8 cm^3 |

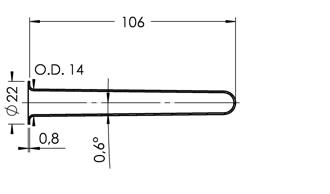

Code: PBN 10-22 Capacity: 10 cm^3 |

|

|

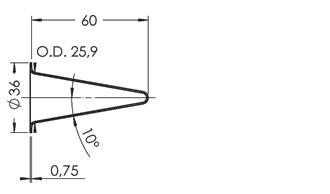

| Code: PBN C12-36 Capacity: 12 cm^3 |

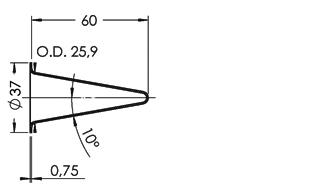

Code: PBN C12-37 Capacity: 12 cm^3 |

|

|

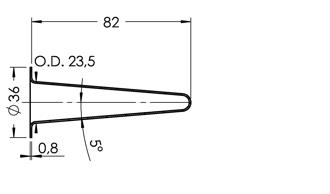

| Code: PBN C16-36 Capacity: 16 cm^3 |

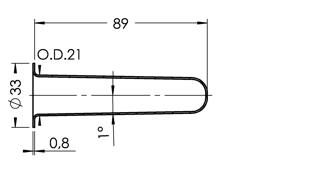

Code: PBN C25-33 Capacity: 25 cm^3 |

|

|

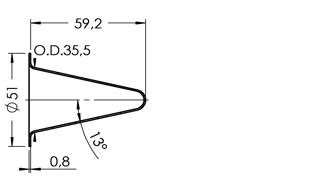

| Code: PBN C25-51 Capacity: 25 cm^3 |

Code: PBN C10-22 Capacity: 10 cm^3 |

|

|

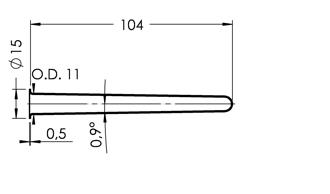

| Code: PBN 35-34 Capacity : 35 cm^3 |

Code: PBN C40-51 Capacity : 40 cm^3 |

|

|

| Code: PBN C60-54 Capacity : 60 cm^3 |

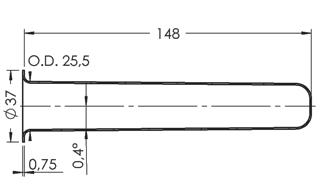

Code: PBN60-37 Capacity : 60cm^3 |

|

|

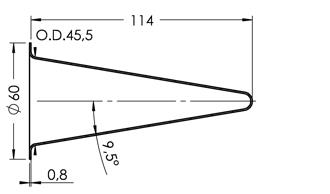

| Code: PBN C70-60 Capacity : 70 cm^3 |

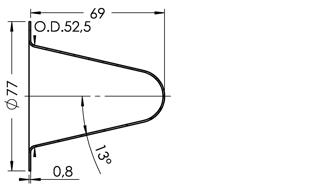

Code: PBN C75-77 Capacity : 75 cm^3 |

|

|

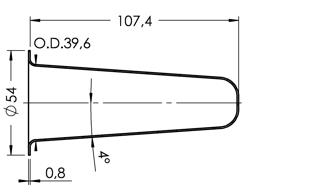

| Code: PBN C80-54 Capacity : 80 cm^3 |

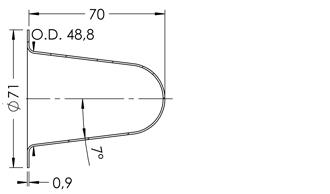

Code: PBN C82-71 Capacity : 82 cm^3 |

|

|

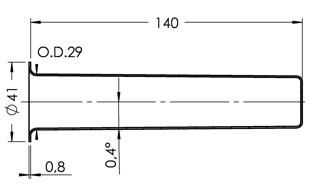

| Code: PBN 85-41 Capacity : 85 cm^3 |

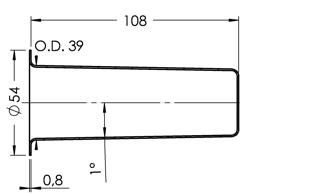

Code: PBN 125-54 Capacity : 125 cm^3 |

|

|

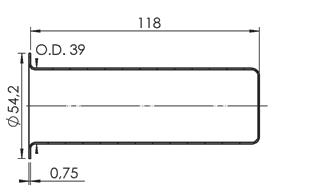

| Code: PBN 130-54 Capacity : 130 cm^3 |

Code: PBN 150-60Capacity : 150 cm^3 |

|

|

| Code: PBN 155-60 Capacity : 155 cm^3 |

Code: PBN 160-60 Capacity : 160 cm^3 |

|

|

| Code: PBN C200-84 Capacity : 200 cm^3 |

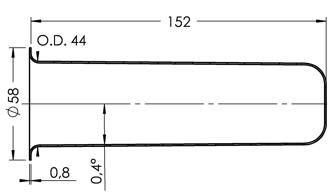

Code: PBN 200-58 Capacity : 200 cm^3 |

|

|

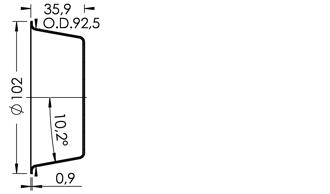

| Code: PBN 200-102 Capacity : 200 cm^3 |

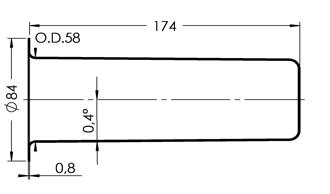

Code: PBN 420-84Capacity : 420 cm^3 |

ACM’s 99.99% purity PBN Crucibles are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Submit your review | |

Worked great for me. I melted down a bunch of scrap copper wire from old TVs in it with a mapp gas torch. It held up great, No cracking for an hour of being heated and didn't leave any ash residue/impurities on the copper. i would describe the size as economical, which is what I was looking for.

This crucible is just the right size for a homemade foundry. We've been able to do dozens of aluminum melts using charcoal with no undue wear on the crucible. It looks like it will hold up for a good while.