- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

Boron nitride is a non-toxic thermal and chemical refractory compound with high electrical resistance and is most commonly available in colorless crystal or white powder form. It is an advanced synthetic ceramic material and is often referred to as “white graphene" or “inorganic graphite", because it has a similar hexagonal platy crystal structure to graphite, but has a much higher oxidation resistance at 800oC.

Boron nitride has high heat capacity, outstanding thermal conductivity, easy machinability, lubricity, low dielectric constant, and superior dielectric strength.

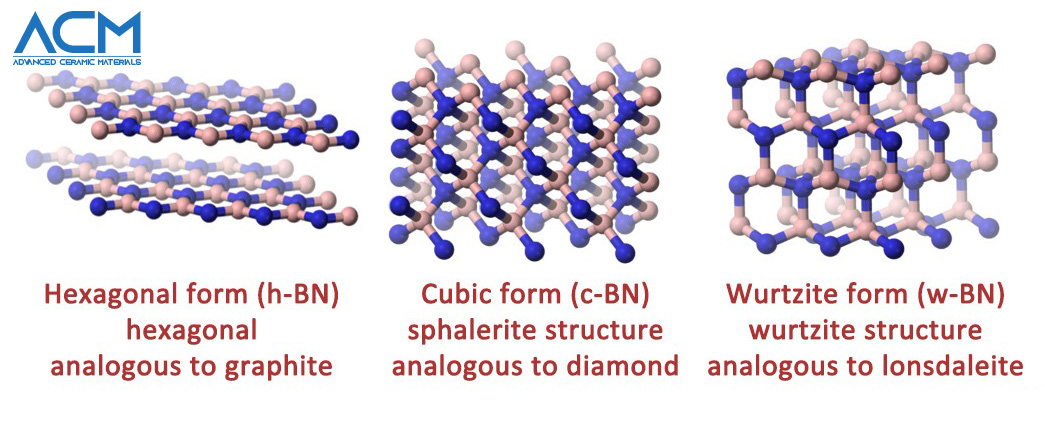

Hexagonal boron nitride (hBN) is a stable phase at ordinary temperature and pressure, and cubic boron nitride (CBN) and wurtzite boron nitride (WBN) can be synthesized at high temperature and high pressure.

Boron Nitride Structures of hBN, cBN, & wBN

The hexagonal form boron nitride (HBN) corresponding to graphite is the softest and most stable form among BN polymorphs and is therefore used as a lubricant and an additive to cosmetic products. HBN can also be produced in graphene-like sheets that can be formed into boron nitride nanotubes.

The cubic boron nitride (CBN) has a high hardness which is inferior only to diamond. But unlike diamond, CBN is insoluble in metals at high temperatures, making it a useful abrasive and oxidation-resistant metal coating.

The rare wurtzite boron nitride (WBN) modification is similar to lonsdaleite, and it may even be harder than CBN.

| CAS#: 10043-11-5, Not Hazardous | |||

| Powder, F.W. 24.82 | |||

| Item No. | Description | Purity | Lot Size |

| NI05-98 | Boron Nitride Powder Particle Size: 3 um, 200 mesh or 325mesh |

BN > 98 %, B2O3 < 0.6%, Ca < 0.015%, Si < 0.12% |

100 kg 1000kg Customize |

| NI05-99 | Boron Nitride Powder Particle Size: 3 um, 200 mesh or 325mesh |

BN > 99 %, B2O3 < 0.4%, Ca < 0.01%, Si < 0.10% |

100 kg 1000kg Customize |

| Grade | BN-BO | BN-SZ | BN-AlN |

| Compositions | BN>98% | BN+SiC+ZrO2 | BN+AIN |

| Binder | B2O3 | / | AlBO3 |

| Density | 2.1-2.2 g/cm3 | 2.3-3.0 g/cm3 | 2.5-2.6 g/cm3 |

| 25°C Volume Resistivity | >1013 Ω·cm | >1012 Ω·cm | >1014 Ω·cm |

| Max. Service Temp. (°C) Oxygen; Inert Gas; High Vacuum |

900 2000 1800 |

900 1700 1700 |

900 2100 1900 |

| Flexural Strength | 75 Mpa | 100 Mpa | 130 Mpa |

| Compressive Strength | 100 Mpa | 300 Mpa | 250 Mpa |

| Coefficient of Thermal Expansion 25-1000°C |

2.0 x 10–6/K | 4.0 x 10–6/K | 4.5 x 10–6/K |

| Thermal Conductivity | 30 W/mK | 40 W/mK | 60 W/mK |

Boron nitride powder has high thermal conductivity, low coefficient of friction, high dielectric constant, and is chemically inert. Due to those unique properties, it is used in a broad range of applications ranging from electronics, aerospace, oil and gas, ceramic manufacturing, and cosmetics.

Boron nitride ceramics are traditionally used as parts of high-temperature equipment because of excellent thermal and chemical stability

BN also has potential use in nanotechnology. Boron nitride nanotubes can be produced that have a structure similar to that of carbon nanotubes, i.e. graphene (or BN) sheets rolled on themselves, but the properties are very different.

H-BN Ceramic is usually used to make BN crucible. C-BN is used as an abrasive and is an ideal material for heat spreaders. W-BN is an ideal dielectric substrate material for optical, electronic, and 2-D graphene-based devices.

China Special Ceramic Parts, Inc. (CSCPI) is a leading supplier of boron nitride ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us for any questions about boron nitride or other ceramic materials that are not listed on the website.