- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

| Compound Formula | BN |

| Molecular Weight | 24.82 |

| Appearance | White |

| Melting Point | 2973 °C |

| Density | 2.1 g/cm3 (h-BN); 3.45 g/cm3 (c-BN) |

| Solubility in H2O | Insoluble |

| Refractive Index | 1.8 (h-BN); 2.1 (c-BN) |

| Electrical Resistivity | 13 to 15 10x Ω-m |

As PBN and graphite are machinable materials, we could offer custom manufacturing services and deliver all kinds of products based on graphite with PBN coating. These including trays, furnace components, heating elements, vaporizing pots, rods, bars, sheets, tubes and more. Our experienced experts are pleased to help to locate best solutions for your development process.

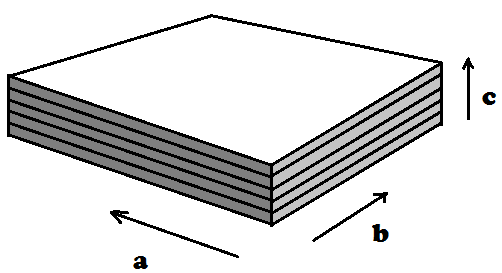

Compared with normal boron nitride ceramic, pyrolytic boron nitride (PBN) has raw materials with a much higher purity level. PBN sheets, discs and other pyrolytic boron nitride products are synthesized on the mold by chemical vapor deposition (CVD) process, with BCl3 and NH3.

BCl3 + NH3 —-> BN +3HCl

Pyrolytic boron nitride China Special Ceramic Parts exhibits high resistance to electricity but good thermal conductivity. It is a high purity material with no porosity which could be deposit on all kinds of graphite shapes by chemical vapor deposition (CVD). Although Pyrolytic boron nitride could be deposited on various materials, it is usually used on graphite only, since the temperature of this CVD process is extremely high and the atmosphere is corrosive. PBN coated graphite materials significantly enhanced the performance of the surface. Better purity, lower porosity and roughness. PBN material could also stand high temperatures (2500`C). As the coated products have great performance in high vacuum and high-temperature circumstances, they are ideal for applications in the semiconductor industry.

|

Item |

value |

Unit |

|

|

lattice constant |

a:2.504×10-10 c:6.692×10-10 |

μ m |

|

|

density |

2.0-2.19 |

g/cm3 |

|

|

resistivity |

3.11×1011 |

Ω·cm |

|

|

tensile strength(ab) |

153.86 |

N/mm2 |

|

|

bend strength |

c |

243.63 |

N/mm2 |

|

ab |

197.76 |

N/mm2 |

|

|

elastic modulus |

235690 |

N/mm2 |

|

|

thermo conductivity |

“a” direction “c” direction |

||

|

(200℃) |

60 2.60 |

W/m·k |

|

|

(900℃) |

43.70 2.80 |

W/m·k |

|

|

dielectric strength(at room temperature) |

56 |

KV/mm |

|

Boron Nitride ceramic from China Special Ceramic Parts, Inc. can withstand high temperature in high vacuum environment, plus it has excellent corrosion resistance and electrical resistance. Thus, Boron Nitride ceramic product is an ideal choice in a wide range of industries, such as:

– Crucibles for crystal growth

– Break rings for horizontal casting machine

– Insulators for high temperature furnace

– Electric insulators in vacuum system

– Feed through for high voltage equipment

ACM’s PBN Machined Products are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Submit your review | |

Great stuff. Strong. Well crafted. Great looking and nice quality.