- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

Aluminum nitride (AIN) is known for its high thermal conductivity and remarkable electrical insulation properties. It is a common ceramic material, used in a variety of electrical devices. Aside from its thermal expansion coefficient and electrical insulation capabilities, aluminum nitride ceramics are resistant to attacks by most molten metals, such as copper, lithium, and aluminum.

These, in combination with several other chemical and physical properties, make aluminum nitride a beneficial material in many industrial applications. In this article, you’ll learn more about aluminum nitride, its different uses, properties, and specific use cases.

Aluminum nitride (AlN) is a non-oxide ceramic material basically composed of aluminum and nitrogen (Al-65.81%, N-34.19), with the chemical formula AlN. It is a solid nitride of aluminum posing a high thermal conductivity of up to 321 W and also serves as an excellent electrical insulator. The aluminum nitride wurtzite phase has a bandgap of ~6 eV at room temperature. Because of these properties, this ceramic has proven useful in many applications, such as optoelectronics operating at deep ultraviolet frequencies.

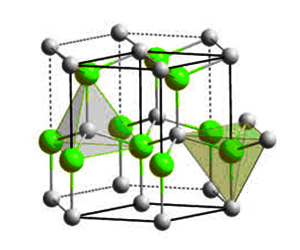

Aluminum nitride structure

Aluminum nitride was first synthesized by F. Briegleb and A. Geuther in 1862. The ceramic material exists mainly in the hexagonal wurtzite crystal structure. However, it is also available in the metastable cubic zincblende phase, which is mainly synthesized as thin films. Studies predict that the cubic phase of AlN can actually exhibit superconductivity at high pressures.

The polycrystalline structure of aluminum nitride (AlN) has high thermal conductivity, accounting for its electrical insulating property. In terms of density, aluminum nitride is a covalent bond compound with a theoretical density of 3.26g/cm3.

Aluminum nitride possesses several properties that make it suitable for a variety of industrial applications:

Aluminum nitride ceramics have been used in many fields due to their favorable properties, including high thermal conductivity, low dielectric constant and dielectric loss, high insulation strength, and their remarkable resistance to plasma erosion. Some of the common applications of this material are:

Another vital use case for aluminum nitride ceramics is in the manufacture of plastics and resins. These materials typically have low thermal conductivity (less than 0.3W/mk). By adding aluminum nitride powder to plastics and resins, they produce thermally conductive potting compounds and thermal pads having high thermal conductivity, which is typically above 10W/mk. They are also used in the packaging of various electronic components.

More researchers are examining the production of light-emitting diodes to operate in the ultraviolet region using gallium nitride-based semiconductors. These studies show that it might be possible to achieve wavelengths as short as 250 nm using the aluminum gallium nitride alloy.

Aluminum nitride has been used extensively in the following applications:

Aluminum nitride crucible

Depending on the method of production and the desired properties, the properties of aluminum nitride can be seen in three different forms:

Today, many manufacturers have mastered producing technical ceramics and constantly provide precision ceramic products to several companies. Organizations or manufacturers that need aluminum nitride ceramic machining, technical ceramic prototyping, ceramic casting, and ceramic metal packaging can turn to trusted ceramics manufacturers for quality technical aluminum ceramic materials.

The high thermal conductivity, high thermal resistance, low expansion coefficient, high mechanical strength, resistance to chemical corrosion, and low dielectric loss of aluminum nitride ceramics make them an ideal choice in various industrial applications.

Thank you for reading our article and we hope it can help you to have a better understanding of aluminum nitride ceramics. For more information, please visit https://www.speciaLceramicparts.com/.