- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

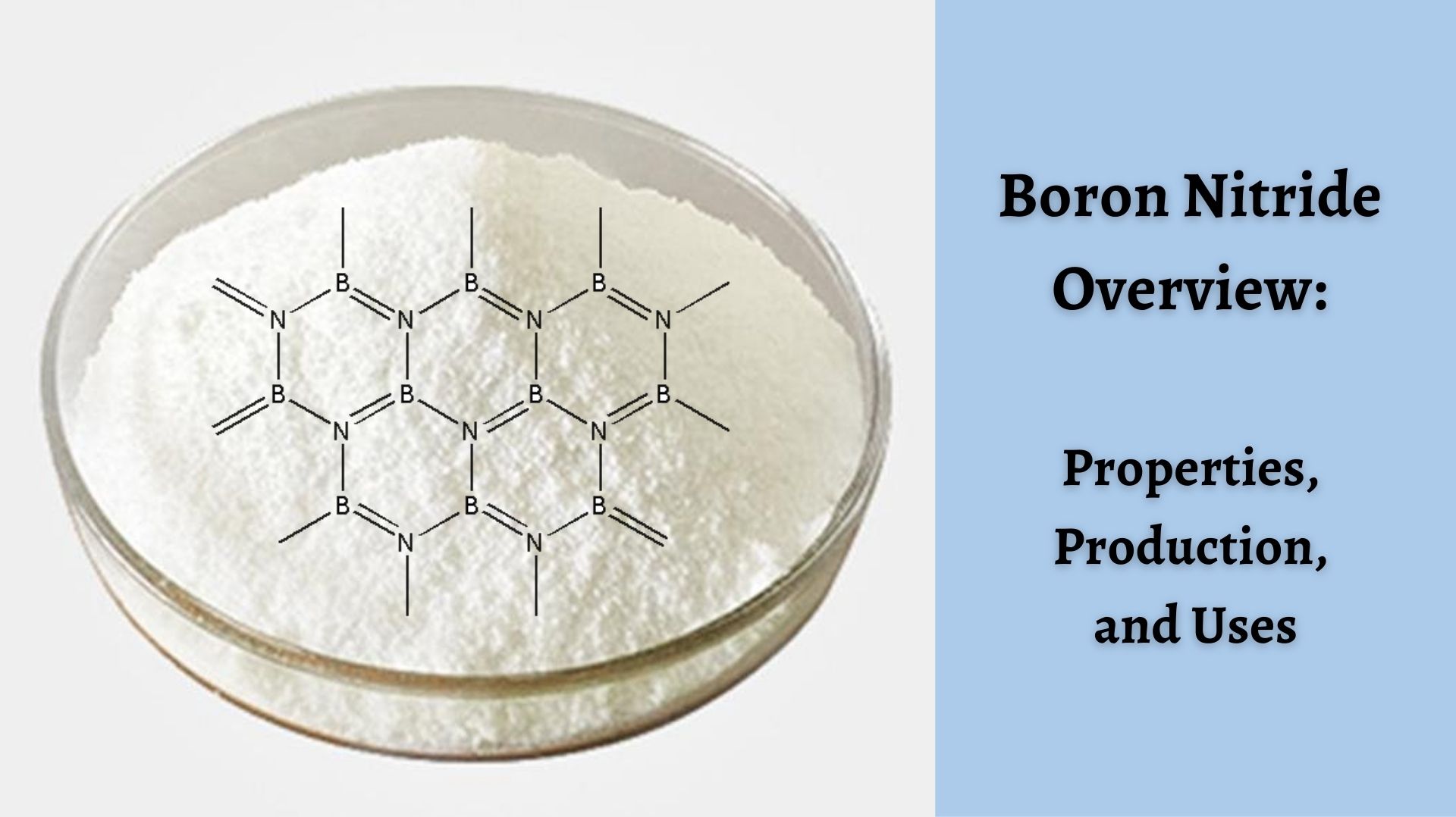

Boron nitride is a non-toxic thermal and chemical refractory compound with high electrical resistance, and is most commonly available in colorless crystal or white powder form. It is an advanced ceramic material and is often referred to as “white graphene” or “inorganic graphite”. In this article, Let’s discuss the production, general properties, and uses of boron nitride.

Boron nitride (BN) is produced synthetically by the reaction of boric acid or boron oxide and nitrogen in the air. Boron nitride uses are vast because of its unique properties, such as good thermal shock resistance, non-toxicity, high thermal conductivity, chemical inertness, etc. It also has a very high melting point (2,973°C).

BN is a chemical compound with an equal number of boron and nitrogen, possessing different properties than other atomic molecules (carbon dioxide (CO) and hydrogen chloride (HCI)), in that it has much to do with carbon. And just like carbon, BN exists in crystalline forms, which are Hexagonal boron nitride, cubic boron nitride, and wurtzite boron nitride. It can be adapted into different shapes (bars, rods, and plates), different forms (powder, solid-liquid, aerosol spray forms), and the grades vary as well (A, AX, 05, HP, M, and M26).

Among all crystalline forms of boron nitride, the most common phases are hexagonal boron nitride (h-BN), which comes in a graphite-like structure, and cubic boron nitride (c-BN), which has a diamond-like structure. Having established a clear definition of boron nitride, let’s go to the different forms of boron nitride, and their uses.

Boron nitride uses are discussed below according to its different forms.

Hexagonal boron nitride is one of the most common crystalline forms of boron nitrides because of its stability. Reacting boric acid with ammonia in a nitrogen atmosphere results in h-BN. Through hot pressing, dense shapes of hexagonal boron nitride can be obtained because of its poor sinterability.

Hexagonal BN is known for its non-abrasive and lubricious nature, including other admirable properties such as low thermal expansion, non-wetting by molten metals, easy machinability, low dielectric constant and loss tangent, high-temperature stability (melting point 2600°C), and chemical inertness (corrosion resistance against acids and molten metals).

HBN Uses: Due to its interesting physical and chemical properties, h-BN is used in different sectors such as plastic, ceramic, paints, alloys, and resins. In the automotive industry, hexagonal BN can be used for sealing oxygen sensors. When mixed with a binder (boron oxide), it can be used as a vacuum. Generally, hexagonal BN is used as an electrically insulating material and heat-resistant material.

The cubic form of boron nitride has similar properties to diamond, but it is not as hard as diamond. Cubic BN is formed when hexagonal boron nitride is treated under high pressure and temperature, much like a synthetic diamond is produced from graphite. Like hexagonal boron nitride, it is also one of the typical phases/forms of boron nitride. But unlike diamond, c-BN can be adopted as an oxidation-resistant metal coating and abrasive due to its insolubility in metals, such as iron, nickel, and related alloys at high pressure.

Cubic Boron nitride has good thermal conductivity, low density, and it exhibits other special properties, such as toughness, fracture, exceptional hardness, high-temperature resistance, and high chemical and thermal stability, similar to hexagonal boron nitride. It is much easier to produce than h-BN. It is also used in grinding high-speed and steel due to the absence of low carbon steel.

CBN Uses: Cubic boron nitride can produce a good insulator, a heat sink in semiconductor lasers. It is popularly used as an abrasive for cutting hardened steel, thermal spraying material, wear resistance cast iron, and many other hard materials.

Wurtzite Boron nitride shares the similar properties as cubic boron nitride, even in hardness. According to scientists, wurtzite BN has been discovered to be harder than cubic boron nitride and diamond. Wurtzite BN is formed like cubic boron nitride (compressing h-BN), but with a difference in the temperature requirement. It occurs at a much lower temperature, close to 1700°C instead of 1730°C and 3230°C like cubic BN.

WBN Uses: In the manufacturing sector, wurtzite BN has recently attracted much attention due to its superior properties and scientific applications, such as an ideal dielectric substrate material for optical, graphene-based devices, electronics, etc. Combined with plate shape particles, wurtzite Boron Nitride can be used as a raw material for sintering coarse grit polycrystalline structure powders. These are then used for manufacturing traditional cutting and grinding tools.

Besides the many valuable applications of boron nitride, it is generally classified as non-hazardous. However, hazardous levels of airborne particulates may be generated if it involves a process that causes the release of dust and fumes, such as grinding, melting, and cutting.

Boron nitride finds wide application in cosmetic industries (eye shadows, lipstick, foundation), paints, and dental cement production, including skincare products. Although more studies are needed to explore BN’s potentials fully, research so far shows that Boron nitride application seems to extend to the biomedical field.

Leave a message

—

Please send your request to special.ceramic@made-parts.com , and we will reply you within 3 minutes.