- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

| Catalog No. | BN1811 |

|---|---|

| Material | BN+SiC+ZrO2 |

| Purity | >99% |

| Density | 2.3-3.0 g/cm3 |

| Shape | Customized |

Boron Nitride is a kind of advanced synthesis ceramic that was sintered at a high temperature and high pressure by BN powder. It has many excellent properties including high-temperature resistance, high thermal conductivity, easy machining, and good lubricity, making BN an outstanding material.

Boron Nitride is a kind of advanced synthesis ceramic that was sintered at a high temperature and high pressure by BN powder. It has many excellent properties including high-temperature resistance, high thermal conductivity, easy machining, and good lubricity, making BN an outstanding material.

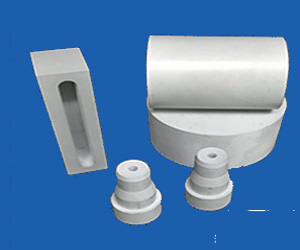

Boron nitride composite ceramic BN-SZ, using silicon carbide and zirconia as a bonding agent, improves the thermal shock resistance and wear resistance of the product. It is commonly used as a separate ring for horizontal continuous casting and a nozzle made of amorphous ribbon. These products have stable chemical properties, high thermal shock resistance, and high corrosion resistance. They are widely used in molten metal contact.

o Chemical stability

o Good wear resistance

o High thermal shock stability

| Grade | BN-SZ |

| Compositions | BN+SiC+ZrO2 |

| Density | 2.3-3.0 g/cm3 |

| 25°C Volume Resistivity | >10^12 Ω·cm |

| Max. Service Temp. (°C) | 900 (Oxygen) |

| 1700 (Inert Gas) | |

| 1700 (High Vacuum) | |

| Flexural Strength | 100 Mpa |

| Compressive Strength | 300 Mpa |

| Coefficient of Thermal Expansion (25-1000°C) | 4.0 10^-6/K |

| Thermal Conductivity | 40 W/mK |

o Used as a horizontal continuous casting separation ring

o Used as metallurgical atomization and powder metallurgy atomizing nozzle

o Used as a thin strip continuous casting side sealing board

o Widely used in the contact of various molten metals

Our Boron Nitride Ceramic BN-SZ is always carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

Submit your review | |

The quality of these are great, and honestly, I just adore the quality of ACM's products.

At this point, I am most definitely now a loyal ACM customer.