- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

Pyrolytic boron nitride is also referred to as chemical vapor-deposited boron nitride. This is because it is produced by chemical vapor deposition. It can be represented as PBN or pyrolytic BN. It is a type of boron nitride ceramic with a hexagonal crystal structure.

Pyrolytic boron nitride has a lot of commendable properties. It is no wonder that this material is highly sought after in various industries. Below are some applications of pyrolytic boron nitride.

Molecular beam epitaxy crucibles are required to have high purity, high resistance to temperature, and excellent mechanical strength. The good news is that pyrolytic boron nitride meets all the criteria mentioned above. Unsurprisingly, pyrolytic boron nitride crucibles are used in molecular beam epitaxy.

Molecular beam epitaxy is a method of depositing layers of atoms on a substrate. The atoms are usually deposited in the form of a molecular beam from the source material. The source material is melted at a high temperature in a pyrolytic boron nitride crucible before it can be deposited.

Compound semiconductors are usually made from chemical elements from two different groups on the periodic table. The crystal of a compound semiconductor can be deposited on a substrate. This occurs using the epitaxial growth method.

For the crystal to be deposited on the substrate, the source material must first be heated at a very high temperature. A high-temperature-resistant crucible is needed for this process. Thankfully pyrolytic boron nitride crucibles are up to the task. Hence, pyrolytic boron nitride crucibles are used in compound semiconductor crystal deposition.

Pyrolytic boron nitride has high resistance to corrosion, excellent resistance to high temperatures, and high mechanical strength. These properties make it ideal as a coating. It is usually used to coat graphite substrates.

When pyrolytic boron nitride is used to coat graphite, it prevents corrosion. In addition, it ensures that the coated object does not react with acids or alkalis. Furthermore, pyrolytic boron nitride has strong adhesion and does not fall off easily from the graphite substrate. It is usually used to coat graphite in environments where carbon is prohibited.

Pyrolytic boron nitride is used as an insulator in heaters. Conventional insulators pose some challenges. These challenges include the presence of impurities, easy corrosion, the release of gasses when exposed to high temperatures, and the inability to insulate at high temperatures.

Fortunately, with pyrolytic boron nitride insulators, most of these challenges are inexistent. Pyrolytic boron nitride is a pure ceramic. Hence impure gasses are not released at high temperatures. In addition, it has a high thermal resistivity and is not affected by high temperatures. All these properties make pyrolytic boron nitride an ideal insulator in heaters.

Some properties of a high-temperature furnace include high mechanical durability, stability at high temperatures, and low coefficient of thermal expansion. Pyrolytic boron nitride has these properties. Therefore, this ceramic material can be used to make high-temperature furnaces.

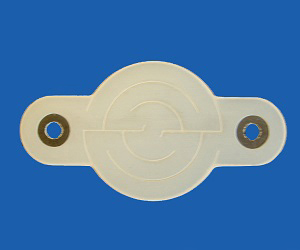

Infrared windows can be used to collect infrared data during live inspection of a device. An infrared window can reduce the incidence of electrocution and an arc flash. Materials used to make infrared windows usually have high mechanical strength, high-temperature resistance, non-toxic, and high resistance to acids.

These requirements tally with the properties of pyrolytic boron nitride. For this reason, pyrolytic boron nitride is used in making infrared windows.

It is the properties of pyrolytic boron nitride that make most of its applications possible. What are some of these properties?

Pyrolytic boron nitride has very high purity. Its purity is up to 99.99%. It is non-toxic and chemically inert. In addition, this ceramic material has excellent thermal shock resistance. This means it is unlikely to crack when there is an abrupt temperature change.

Pyrolytic boron nitride has low thermal conductivity. Furthermore, it has a low coefficient of thermal expansion and low thermal resistivity. The density of this material is about 2.15 g/cm3 while its tensile strength is 153.84 N/mm2.

Pyrolytic boron nitride is of great use in various industries. Its wide use can be credited to some of its excellent properties. Some of these properties include its high purity and resistance to corrosion. Research is still ongoing on how these properties can pave a way for pyrolytic boron nitride in different sectors. For more information about ceramic materials, please visit https://www.speciaLceramicparts.com/.

Further Reading:

What is Pyrolytic Boron Nitride (PBN)?

Structure & Features of Pyrolytic Boron Nitride

Introduction of Pyrolytic Boron Nitride (PBN)