- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

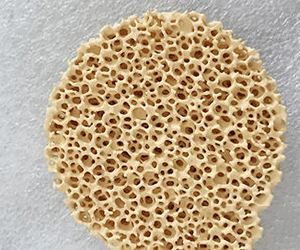

| Catalog No. | OX2690 |

|---|---|

| Color | Dark Yellow |

| Form | Block / Disc/ Ring |

| Compositions | ≥80% MgO |

| Working Temperature | ≤1000℃ |

| Pores Per Inch | 8-60 |

Magnesia Ceramic Foam Filter is applied to purge and filter the solution of magnesium and magnesium alloy. Since magnesium alloy is more vivacious than other nonferrous metal, magnesium alloy solution can easily react with the main-material of the ceramic foam filter and liquate rapidly ceramic filter. After using this product, it has an obvious effect on reducing slag and porosity of castings, and the test of casting performance shows that it has an obvious effect on improving the inner quality of castings.

Magnesia Ceramic Foam Filter is applied to purge and filter the solution of magnesium and magnesium alloy. Since magnesium alloy is more vivacious than other nonferrous metal, magnesium alloy solution can easily react with the main-material of the ceramic foam filter and liquate rapidly ceramic filter. After using this product, it has an obvious effect on reducing slag and porosity of castings, and the test of casting performance shows that it has an obvious effect on improving the inner quality of castings.

|

Volume Density |

0.5~0.7g/cm3 |

|

Bore Density |

10-60ppi |

|

Porosity |

80-90% |

|

Bending Strength |

0.6Mpa |

|

Compression Strength |

≥0.8Mpa |

|

Thermal Shock Resistance |

1100°C—room temperature 6 times |

*High porosity

*Low loss of thermal shock

*High mechanical strength at normal and high temperature

*Large specific surface

*Good chemical stability

*Excellent filtering functions of screen

*Excellent filtering residua collection and absorption

-Purge and filter solution of magnesium and magnesium alloy