- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

In the past few years, structural ceramics have maintained a strong and sustained growth, which is not only due to the growth of many different application fields but also due to the exploration and attention of ceramic materials science. As demand continues to grow, people need stronger, lighter more durable and resistant materials to do more impossible tasks, so material manufacturers must seek new and innovative processes to produce the next generation of ceramics.

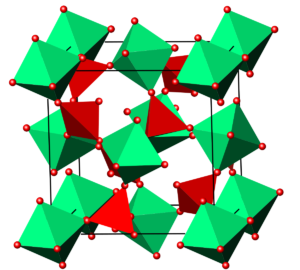

Zirconia, alumina (Al2O3), silicon carbide (SiC), aluminum nitride and silicon nitride (AlN and Si3N4), as well as aluminum-zirconium oxide complexes (commonly known as ATZ toughened zirconia) and zirconia toughened alumina (ZTA), are the most commonly used ceramic materials. With the development of science and technology, a new type of structural ceramic material called zirconium tungstate has also attracted wide attention, which has been applied in aerospace industry and precision industries such as national defense.

Zirconium tungstate ceramic is a peculiar material. Normally, thermal expansion and cold shrinkage are the physical phenomena of most materials, but zirconium tungstate ceramic materials can show the physical phenomenon of thermal shrinkage and cold expansion. This material is called near-zero negative thermal expansion material.

Zirconia ceramics have excellent mechanical properties and are widely used in structural parts. Zirconium tungstate has a high negative expansion coefficient, and its negative thermal expansion characteristics are always maintained within the temperature range of 0. 3~1050K, and its performance is isotropic. All these excellent properties have laid a good foundation for the wide application of zirconium tungstate. It is commonly used to combine zirconia (or alumina) and zirconium tungstate in a certain ratio, so as to achieve low expansion performance and maintain the integration of carrying capacity and structural functions of materials. Due to its low thermal expansion coefficient, ZrO2/ZrW2O8 ceramic matrix composites have wide application prospects in precision instrument manufacturing, optics, aerospace, electronics and other fields.

Near-zero expansion ceramics are widely used, and these materials also include zirconia and alumina, each of which has its own characteristics. In general, zirconium tungstate performs well in negative thermal expansion, stability, mechanical properties, fracture toughness and conductive thermal conductivity in high temperature and cold environment, except for its slightly expensive price. Some scientists believe that if zirconium tungstate can reduce the production cost, the near-zero negative thermal expansion ceramic material based on zirconium tungstate will lead to a large-scale upgrade in aerospace equipment, laser equipment, optical communication systems, and microelectronics.

Stanford Advanced Materials supplies high-quality tungsten and other metal products to meet our customers’ R&D and production needs. Please visit http://www.samaterials.com for more information.