- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

Zirconia, or zirconium oxide, is a white crystalline oxide of zirconium. It is now popular in the field of medical hard tissue repaired because of its dense texture, abrasion resistance, smooth surface, good biocompatibility and chemical stability. The first proposal to use zirconia for medical purposes was proposed in 1969, and it involved orthopedic applications. The proposal decided to use Zirconia, instead of titanium or alumina prostheses, as a new material for hip head replacement.

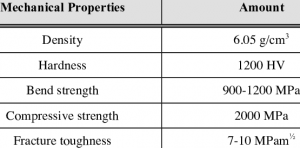

Influenced by the mechanical behavior of medical ceramics because of its micro-structure and chemical composition, zirconia ceramics have a better mechanical performance as medical ceramic. Zirconia has mechanical properties similar to those of stainless steel. Its resistance to traction can be as high as 9001200 MPa and its compression resistance is about 2000 MPa. Cyclical stresses are also tolerated well by this material.

Due to its stable chemical performance, zirconia ceramics can resist body fluids under the normal physiological metabolism without metamorphism, so the coating can be used for metal implant materials.

The porous skeleton made by zirconia used for bone substitute material can withstand the load, on which surface layer overlies hydroxylapatite to promote bone conductibility and enhance the role of bioactive materials.

Compared to other restorative materials, such as the titanium mentioned above, less inflammatory reactions in human tissues were observed by using zirconia. This result was confirmed by a study comparing the soft tissue around the implant around the zirconia repair cap with the soft tissue surrounding the titanium. In the experiment, it was found that the inflammatory infiltration, microvessel density and vascular endothelial growth factor expression around the titanium cap were higher than around zirconia. In addition, the level of bacterial products, measured with nitric oxide synthase, was higher on titanium than on zirconium oxide.

ZrO2 stabilized with Y2O3 has better mechanical properties than other combinations; although its sintering is much more difficult, this is the principal kind of zirconia considered for current medical use. Yttria is added to stabilize the crystal structure transformation during firing at an elevated temperature and improve the physical properties of zirconia. Upon heating, the monoclinic phase of zirconia starts transforming to the tetragonal phase at 1187 °C, peaks at 1197 °C, and finishes at 1206 °C. On cooling, the transformation from the tetragonal to the monoclinic phase starts at 1052 °C, peaks at 1048 °C, and finishes at 1020 °C, exhibiting a hysteresis behavior. The zirconia tetragonal-to-monoclinic phase transformation is known to be a martensitic transformation.

For more information, please visit https://www.speciaLceramicparts.com/.

Copyright (c) 1994-2022 China Special Ceramic Parts, Inc. owned by Oceania International LLC, All Rights Reserved.