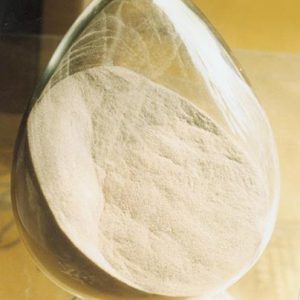

- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

Alumina is the most common and cheap ceramic material. Due to its high hardness, high modulus of elasticity and thermal shock resistance, alumina has been applied to high temperature environments such as protective tubes and low friction applications, sliding bearings in pumps. Thanks to its high hardness and excellent high temperature durability (maximum operating temperature is up to 1500 C), alumina becomes a reliable application material.

Technical ceramics refer to inorganic ceramic materials that can combine physical properties and thermal properties. This material replaces some conventional materials to achieve their desired performance. The emergence of technical ceramics has opened up a new situation for the fields of mechanical engineering, casting, automobile and textile industry, as well as electronic and medical fields.

High-tech materials have many advantages such as low density, chemical stability, excellent resistance to electricity, high hardness and heat resistance, corrosion resistance, etc. Technical ceramics are often used for corrosion resistance, wear resistance, and high temperature resistance. The use of technical ceramics not only reduces costs, but also prolongs the service life of the product.

Alumina is the main component of Ruby and sapphire, because of other impurities and different colors, sapphire is containing iron oxide and titanium oxide.

The aluminum reacts with oxygen in the air to form a dense layer of alumina film, it exposed to the air covering the surface of the aluminum.

Aluminum is a good conductor of electricity and heat. The crystalline form of alumina is suitable for use as abrasive materials and cutting tools because of its high hardness.

Medium alumina powder is used as media for color layer analysis.

Alumina is made from fused alumina from high alumina deposits, while high-grade aluminates are used to produce powder corundum and white corundum. Their natural crystal structure makes them high hardness and quick to cut. At the same time, they are often used as raw materials for consolidation abrasives and coated abrasives.

Alumina can be recycled many times. The cycle times are related to the material grade and the specific process. Most of the standard abrasive blasting equipment can be used.

Applicable industries: aerospace industry, automotive industry, consumer products processing, casting, OEM distributors, semiconductor industry and other fields.

Applicable process: surface electroplating, paint, coating and pretreatment of glazed PTFE; aluminum alloy products and deburring, scaling; mold cleaning; pretreatment metal sandblasting; dry grinding and wet grinding; precision optical refraction; mineral, metal, glass and crystal grinding; glass engraving and paint additives.