- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

Precise ceramics are new materials which have stable and reliable anti-static performance by high temperature sintering molding. During the manufacturing process, special inorganic materials are added into the clay, and the sintering temperature should reach 2480°F. Precise ceramics can be categorized into structural ceramic and functional ceramic.

Structural ceramics can work as building materials. With high strength, hardness, elastic modulus, structural ceramics have the qualities of high temperature resistance, wear resistance, corrosion resistance, oxidation resistance, thermal shock resistance.

The chemical equation of silicon nitride is Si3N4. It is a super hard and lubricious atomic crystal with wearability and oxidation resistance. Silicon nitride ceramic won’t break even through a rapid cooling after heated to 1832°F, therefore it has been widely used to manufacture bearings, gas turbine blades, mechanical seal rings, permanent molds and other mechanical components. When heat-proof silicon nitride is made into the heating surface, the car engines can not only improve the quality of diesel engines, but also improve efficiency and save fuel. Silicon nitride ceramic is regarded as one of the most potential material for cutting tools since it has great overall performance and rich resources. Now, about 140 tons of silicon nitride powder is applied in knife manufacturing each year, worth about 300 million US dollars.

Silicon Nitride Knives

The main composition of silicon carbide ceramic is SiC. With the hot pressing process, silicon carbide ceramic has strong density and high hardness. The bending strength of silicon carbide ceramic can reach 500 to 600 MPa even at a high temperature of about 2552°F. Silicon carbide is considered as one of the most intensive materials in high temperature condition. Its thermal conductivity ranks second place after that of beryllium oxide ceramic. Silicon carbide ceramic concludes oxidation resistance, electrical conductivity and high impact toughness qualities. Therefore, silicon carbide can be used in rocket tail nozzle, thermocouple casing, furnace tubes and other production parts under great heat. There are more applications of silicon carbide ceramic, such as producing heat exchanger, grinding wheel and sealing ring for carrying strong acid or strong base.

The main component of alumina ceramic is Al2O3. As a well-balanced material, alumina ceramic is used to manufacture thick film integrated circuit. Alumina ceramic has good conductivity, mechanical strength and high temperature resistance and other qualities. Because of its excellent functions, alumina ceramic has been widely used in daily life and for special needs. However, alumina ceramic needs ultrasonic cleaning.

Alumina Ceramic

Pure Zirconia is white crystal with m-ZrO2, t-ZrO2 and c-ZrO2 three states under different temperatures. Impure zirconia usually is yellow or grey with HfO2. There has been about 19 million tons of zircon resources proved on earth so far. Zirconium oxide is usually made from zirconium ore purification. Zirconia ceramic concludes varied qualities, such as high melting point and boiling point, great hardness, insulation at room temperature and conduction under high temperature. Zirconia ceramic is a material with multiple applications. Related products conclude Y-TZP grinding ball, dispersing and grinding media, nozzle, ball seat, zirconia mold, mini fan shaft, fiber optic pin, fiber sleeve, drawing die and cutting tools, antifriction knives, clothing buttons, straps, bracelets and pendants, ball bearings, lighter golf ball bats and other accessories. Besides, Zirconia ceramic is also widely used in thermal barrier coating, catalyst carrier, medical, health care, refractory materials, textile and other fields.

Functional ceramics have strong reaction to physical quantities, like electricity, magnetism, light, heat or chemical, biological phenomena. Besides, functional ceramic materials can convert these phenomena or exchange their values to each other.

The most commonly used insulator is Al2O3. Recently, there are new insulator materials. For example, AlN ceramic has many excellent qualities such as high strength, high insulation and thermal conductivity, low dielectric constant, and so on. Besides, its thermal expansion coefficient is the same with that of monocrystalline silicon, therefore AlN ceramic can be used into heat dissipation substrates of large scale integrated circuits and power module circuits.

The conductivity of semiconductor ceramic will have great changes if the outside conditions (temperature, lights and electric field) change. Therefore, semiconductor ceramic can help transfer the outside physical quantities into electric signals. There are many sensitive components made from semiconductor ceramic. For example, thermal sensitive porcelain can sense tiny temperature changes, which is used for measuring and controlling the temperature.

Piezoelectric ceramic can help mechanical energy and electrical energy convert into each other. Piezoceramic Material has been widely applied into medical imaging, acoustic sensors, acoustic transducers and ultrasonic motors because it consists of good qualities like piezoelectricity, dielectricity and elasticity. Under the mechanical stress, the internal positive and negative charge center of piezoelectric ceramic have relative displacement and polarization, which leads to bound charges at the two ends of the surface with opposite symbols. Highly sensitive, highly stable piezoelectric ceramic materials, electrostrictive ceramic materials, pyro electric ceramic materials are representatives of new piezoceramic materials.

Piezoceramic Materials

Magnetic ceramics can be divided into two types. One is called hard magnetic material and the other is soft magnetic material. Ferrite magnets and rare earth magnets are representatives of hard magnetic materials, which are mainly used for manufacturing magnets and magnetic storage components. Soft magnetic materials are easy to magnetize and demagnetize, and the direction of its magnetic field can be changed. Therefore, they can be used in producing electronic components responding to alternating magnetic fields.

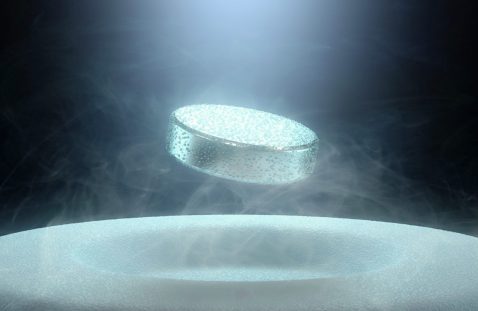

Superconducting ceramics refers to ceramic materials with superconductivity. They have zero resistance at a certain critical temperature as main character. Nowadays, high temperature superconducting materials are developing in high current applications, electronics applications, magnetic resistance and other relating aspects.

superconductor

Anti-bacterial ceramic is a kind of porcelain with anti-bacterial function. Inorganic antibacterial agents are added into the porcelain products. Therefore, the ceramic has antibacterial effects. Anti-bacterial bone china can inhibit or kill the bacteria when being used. Anti-bacterial ceramic can effectively avoid a variety of infectious diseases against human beings, especially making contributions to pubic sanitation and health.

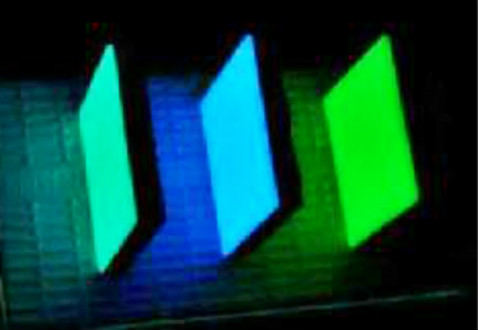

Luminescent ceramic is a high-purity and high-teach material by processing the rare earth materials under high temperature and high pressure. This ceramic can absorb sunshine and other scattered light. Then it can be activated after accumulating light energy, which giving out strong lights in the dark for over 12 hours. Besides, the lightening function can maintain for about 15 years.

Luminous Ceramic