- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

Improving the potential and reliability of components in gas-turbine engines operating in conditions of high thermal and aerodynamic stress is closely linked with the need to improve ceramic parts used in the production of complex articles from nickel, heat-resistant alloys.

There is a comprehensive investigation aimed at developing thermalshock resistant refractories based on corundum-mullite materials possessing high metal resistance to heat-resistant nickel alloys, and which are used for making crucibles for precision casting of the blades of gas-turbine engines (GTE), the production of measured blanks of heat-resistant alloys, and saggers for firing rods.These investigations established that it is possible in theory to increase the thermal-shock resistance of high-alumina ceramics with a low porosity and sufficiently high mechanical strength. This was achieved by forming a microcracked, fragmented structure by introducing coarse-grained additions of sintered multite, electrocorundum, silicon carbide, and electrofused zirconium dioxide. It was shown that the thermal-shock resistance depends on the concentration of microcracks and the size of the fragments; and, moreover, the increase in the thermal-shock resistance is greater the more the temperature coefficient of linear expansion (TCLE) of the additive differs from that of the high-alumina matrix.

The increase in the labor productivity and the quality of the engine blades, cast in vacuum induction furnaces (designate UPPF), are mainly determined by the thermal-shock resistance of the ceramic crucible and the degree of contamination, from the molten metal. Rammed crucibles that were used in this work, and which lasted (with intermediate repairs) up to 400 castings, are eroded by the chemically active alloys, and are a source of dirt and blisters, as a result of which the total loss of blades due to metal contamination reaches 60-80 %.

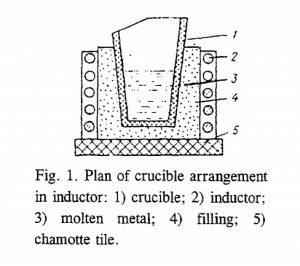

Scientists therefore developed corundum-mullite material TSM-323 and a production technology for changeable ceramic crucibles, height 320 mm, internal diameter about 135 ram, and wall thickness 18 mm for use in UPPF furnaces, and VIP-3 furnaces (Fig. 1). The enhanced thermal-shock resistance of TSM-323 is due to the formation of a fragmented structure. During a final firing at 1580~ the high-alumina matrix undergoes shrinkage, and the grains of mullite prevent this. As a result, the matrix is broken into several fragments that are capable of being mutually displaced and thereby resisting thermal shock.

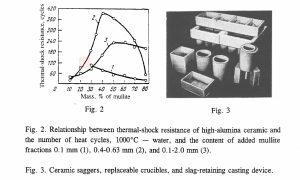

It is found that the highest increase in thermal-shock resistance is attained by introducing into the ceramic composition sintered mullite grade MLO-62 and MKO-72 (TU 148-871) with grain sizes of 0.4-0.63 mm (Fig, 2). The phase composition of the ceramic consists of corundum (a-A1203), mullite (3A1203-2SiO2), strontium anorthite (Sr2A12Si2Os), and strontium titanate (SrTiO3). The ceramic has a high refractoriness — 1740℃.

The crucibles were made by hot vibration-forming from thermoplastic slips. During shaping the vibration oscillations during the application of pressure prevented layering of the slip at the moment of casting up of the body, and ensured that good quality blanks were obtained with uniform density.

Industrial tests on the crucibles made of TSM-323 in UPPF furnaces showed that the yield of acceptable blades after luminescence (LYuM) control testing from the first application, when alloys VZhL-8U, VZhL-12U, and ZhS-6K ‘were being melted, compared with these factors with the use of rammed crucibles, increases 1.5-2 times and reaches 80-90%. The loss due to contamination is reduced by 35-45 %, and the total yield of acceptable blades is increased by 10%. In terms of the short-term strength and prolonged heat resistance, the alloys completely satisfied the technical specifications. The chemical composition of the alloys after tenfold heating in the crucibles did not change. The life of the crucibles is 150-200 castings (7-8 shifts) at alloy reheat temperatures of 1600-1700~ they possess high mechanical strength and shock resistance, and are reliable in service. Their use in place of rammed articles would exclude the precalcination operation and attachment of drainage trays.

High quality blanks, diameter 90 mm and mass 12-13 kg from heat-resistant alloys were obtained by developing slagretaining casting equipment, designed for purifying the metal from slag inclusions, and casting in 15 mill 600 kg of liquid metal at 1500-1600~ in an ISV-06 vacuum smelting furnace. The equipment included slag-retaining units measuring 895 x 280 x 130 mm, four casting trays measuring 580 x 450 x 135 mm, and 48 chill molds, external diameter 120, and height 260 ram.

Considering the large dimensions, complex geometry, and the need to provide increased green strength, the slag retainers and trays were made by vibrocasting in metal molds using a self-hardening organic bond and ethyl silicate-40. After forming, the articles were dried naturally in air and fired at 1550~ in a gas-fired tunnel kiln. The ingot molds were shaped by cold vibrocasting with ethyl silicate and water bonds in gypsum molds and fired also at 1550℃.

The results of industrial tests of the different designs for the slag retainers in the ISV-06 furnace showed that the designs that were developed and the ceramic materials all satisfy the specifications, and are suitable for casting heat-resistant alloys VZhL-12 at 1500-1600~ The slag is removed; the OTM-952 and OTM-953 are not wetted by the metal; the cast blank is removed from the ingot mold without damage.

Firing of the thin-walled ceramic rods in the production of the GTE blades is done in ceramic saggers in an alumina filling. The saggers should have a long working life, should not deform in firing, and should be made of readily available materials. The saggers used in regular production have a life of 8-10 cycles at 1350~ they are made from OTM-451 material containing 62 % scarce electrocorundum fractions No. 80, 50, 4, and M50.

In order to increase the life and reduce the consumption of electrocorundum, scientists also developed corundum-mullite material OTM-958. This contains 25% sagger scrap, 30% mullite, 30% alumina, and 15% electrocorundum. Material OTM-958 possesses a well, developed microcracked structure which boosts thermal-shock resistance; it contains 50% less electrocorundum than OTM-451. The life of the saggers was 15-16 cycles, which is 50% higher than the life of those made from OTM-451. The saggers were shaped by vibration casting using ethyl silicate bond, and then fired at 1550~ in a gas-fired tunnel kiln.

Following a series of material-behavior and technological investigations, scientists developed heat-resistant corundum-mullite materials TSM-323, OTM-952, OTM-953, and OTM-958, with good thermomechanical properties. The smelting crucibles and the saggers made from them (Fig. 3) are being effectively used in the regular production of GTE blades.