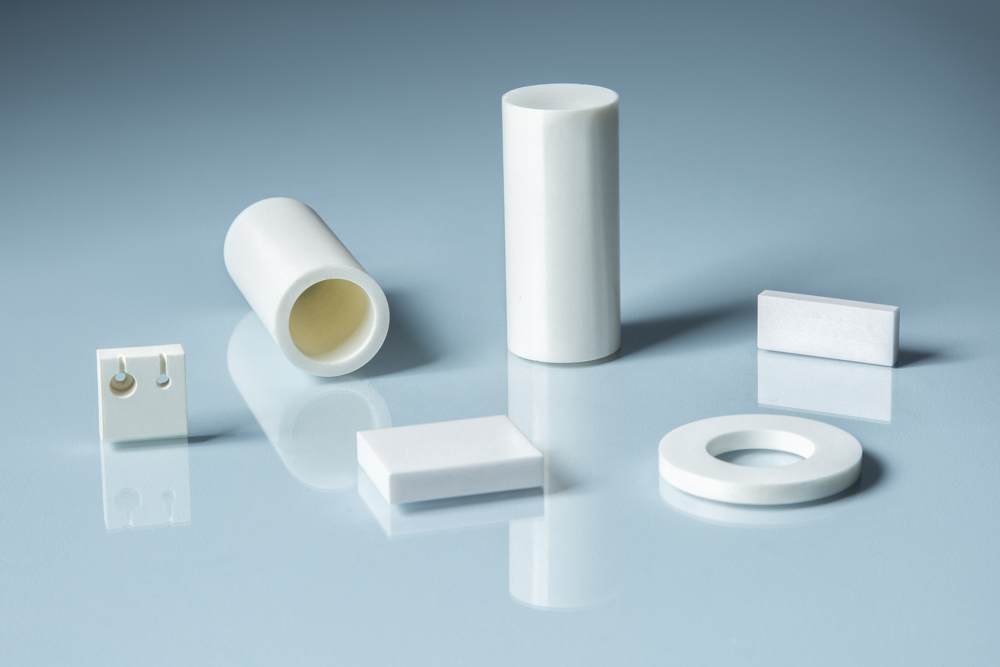

- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

The content of zirconium in the earth’s crust is 0.025%, which is more than copper, zinc, and lead that are commonly used in industry. Zirconium in nature mainly exists in the form of zirconium quartz, plagioclase, water zircon, eutectic crystal, sodium feldspar and other minerals. The main component of zirconium is ZrSiO4, which is a very stable compound formed by strong bonds between ZrO2 and SiO2.

Zirconium dioxide has excellent heat resistance, corrosion resistance, and plasticity. Apart from a large number of applied to refractory, zirconium dioxide is widely used in the manufacture of the piezoelectric element, ceramic capacitors, gas sensor, solid electrolyte battery, ceramic internal-combustion engine, optical glass and zirconium dioxide fiber and zirconium catalyst, which is one of the most promising functional materials in the 21st century. However, conventional zirconium dioxide heat has some defects such as poor stability, small specific surface and underdeveloped pores, which limit its performance and application.

Nanometer zirconia has many excellent physical, chemical and material technological characteristics. For example, the ceramic formed by zirconia powder has become one of the main structural ceramics because of its good properties of phase change and toughening; nano-zirconium dioxide has been used as a dispersive relative matrix for strengthening and toughening in the study of nano-composite materials; as an ideal electrolyte, stable zirconia has been widely used in solid oxide fuel cells.

The special structure and properties of nano-zirconia have shown a wide application prospect in the fields of electronics, metallurgy, aerospace, chemistry, environment, biology and medicine. Zirconium dioxide, for example, is a high-tech cosmetic and dental restorer developed only in recent years, which is made by computer-aided design, laser scanning, and grinding controlled by a computer program. Some of its properties have exceeded that of metal, making it the most ideal all-china tooth and porcelain tooth.

Please visit http://www.samaterials.com for more information.