- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

Silicon carbide (SiC) ceramics have excellent properties such as oxidation resistance, high-temperature strength, chemical stability, thermal shock resistance, thermal conductivity and good air tightness, which have been widely used in the fields of energy, metallurgy, machinery, petroleum, chemical industry, aviation, aerospace and national defense.

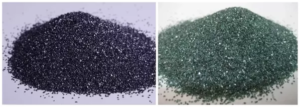

Habitually, silicon carbide used in the abrasive industry can be divided into black silicon carbide and green silicon carbide according to its color, both of which are hexagonal crystal.

Black silicon carbide contains about 98.5% of SiC, which is mainly made from quartz sand, petroleum coke, and high-quality silica as the main raw materials and smelted by resistance furnace at high temperature. Its toughness is higher than green silicon carbide, and it is mainly used for processing materials with low tensile strength, such as glass, ceramic, stone, refractory, cast iron, and non-ferrous metals.

Green silicon carbide contains more than 99% SiC. It is made from petroleum coke and high-quality silica as the main raw materials, with salt added as the additive and smelted by resistance furnace at high temperature. It has good self-sharpening property and is mainly used in the processing of hard alloy, chin alloy, and optical glass, as well as wear-resisting cylinder sleeve and precision grinding high-speed steel cutter.

The properties of silicon carbide ceramics are superior to those of other new types of ceramics. For example, alumina (Al2O3) ceramics with relatively low sintering temperature, low cost, and good electrical insulation have been widely used, however, the application of which in high power circuits is limited because of its low thermal conductivity; beryllium oxide (BeO) ceramics have good comprehensive dielectric properties and are used as high thermally conductive substrate in some fields, however, Europe, America, Japan and other places are now issuing regulations to restrict the sales and research and development of electronic products containing BeO due to its toxicity; aluminum nitride (AlN) ceramic has excellent thermal conductivity and electrical insulation, and low dielectric constant, so it is suitable for high power circuit, however, the sintering temperature of AlN ceramics is too high, which leads to the complex preparation process and high cost. Therefore, it has not been produced and applied on a large scale.

Silicon carbide ceramics have many advantages, such as low density, high mechanical strength, good oxidation resistance, wear resistance, excellent thermal shock resistance, and low thermal expansion coefficient, etc. It has good development and application prospects in the field of electronic products, which can meet the requirements of high performance, small lightweight and high reliability of electronic equipment in the future.

Please visit http://www.samaterials.com for more information.