- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

| Catalog No. | AC3286 |

| Material | Al2O3 |

| Purity | ≥95 |

| Density | 3.6g/cm3 |

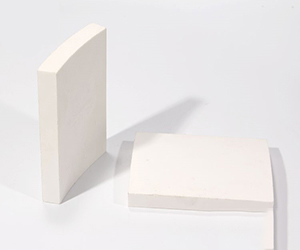

Mosaic wear-resistant ceramic sheets are made of special corundum ceramics Al2O3 as the main raw material, rare metal oxides as flux, and fired at a high temperature of 1700 ℃, and then combined with high-strength organic/inorganic adhesives. Its Rockwell hardness is HRA80-98, which is second only to diamond and far exceeds the wear resistance of wear-resistant steel and stainless steel. It features good wear resistance and low density, so it can greatly reduce the equipment load.

Mosaic wear-resistant ceramic sheets are made of special corundum ceramics Al2O3 as the main raw material, rare metal oxides as flux, and fired at a high temperature of 1700 ℃, and then combined with high-strength organic/inorganic adhesives. Its Rockwell hardness is HRA80-98, which is second only to diamond and far exceeds the wear resistance of wear-resistant steel and stainless steel. It features good wear resistance and low density, so it can greatly reduce the equipment load.

| Specification | Parameter |

| Content (Al2O3) % | ≥95 |

| Density (g/m3) | ≥3.5 |

| Rockwell Hardness | ≥80 HRA |

| Compressive Strength | ≥850 Mpa |

| Fracture Toughness KIC | ≥4.8Mpa·m^(1/2) |

| Flexural Strength | ≥290Mpa |

| Thermal Conductivity | 20W/m.K |

| Coefficient of Thermal Expansion | 7.2×10^(-6)m/m.K |

| Common Specifications | ||

| Length (mm) | Width (mm) | Thickness (mm) |

| 10 | 10 | 3-10 |

| 17.5 | 17.5 | 3-15 |

| 20 | 20 | 4-20 |

| 24 | 24 | 10 |

Used as a wear-resistant material for material conveying equipment in petroleum, mining, steel mills, power plants and other industries or liquids flowing through the surface of pipelines.

Our Mosaic Wear-resistant Ceramic Sheet is carefully handled during storage and transportation to preserve the quality of our product in its original condition.