- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

There are many kinds of precise ceramic producing methods. The production of precise ceramics should be based on product’s shapes. Different forming methods need to be combined with different bonding agents. Common ceramic forming methods are listed as follows.

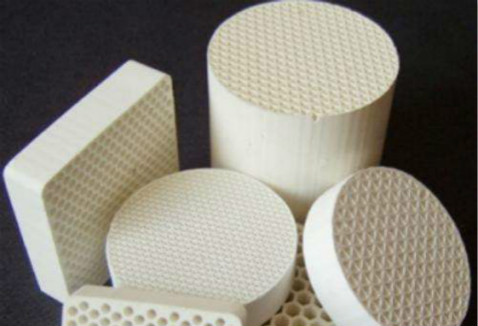

Extrusion molding is using hydraulic press to push the piston, and then squeezing plasticized embryo material out of the extrusion nozzle. With the inner parts of the squeeze nozzle gradually becoming smaller, the piston has a great squeeze force on the mud. At last, the embryo becomes dense and forms into the final shapes. Extrusion is widely used in manufacturing bricks, tiles, pipes, rods and elongated parts with equal cross-section. Sections with complicated shapes can also use the extrusion. The most representative product is honeycomb ceramic for automotive exhaust emissions.

Honeycomb Ceramic

The mill powder of long wear small ball is preferred since it has great fineness and round shapes. Use proper amount of solvent, plasticizer, binder and other dosage. The mud material needs to have great uniformity to ensure the quality of the extruded embryo body.

Little pollution with automatic operation is one of the strengths of extrusion molding. Besides, this processing method can be used in continuous production with high efficiency, which is suitable for tubular, rod-like products.

The structure of squeeze nozzle is complicated and it requires high precision. In addition, since there are a lot of solvent and binder in the slurry, embryo in the drying and firing stages are likely to shrink leading to unstable performances.

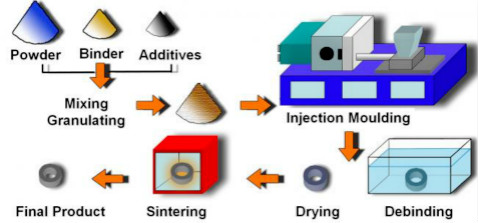

Ceramic Injection Molding (CIM) is a branch of modern powder injection molding. Ceramic injection molding technology is derived from injection molding of polymer materials. It realizes the formation with the characteristic that polymer melts at high temperature and solidify at low temperature. Then, the polymer can be removed after molding. A variety of complex shapes of high-precision ceramic parts can be manufactured with this processing technology. It’s much easier than the traditional ceramic processing and can be used in scale and automated production.

CIM has some special technical advantages. The processing procedures can be precisely controlled even when CIM is applied in fast and automatic mass production. CIM is good for manufacturing the products with wet green of high strength, high dimensional accuracy, less mechanical processing, and uniform bodies. It has great superiority in producing products with complex shapes and thin thickness. However, since CIM concludes a large amount of a polymer binder, therefore there are drawbacks that the blank is easily deformed and pores are easily formed. It has become an insurmountable problem to degrease the ceramic green body.

Injection Molding Process

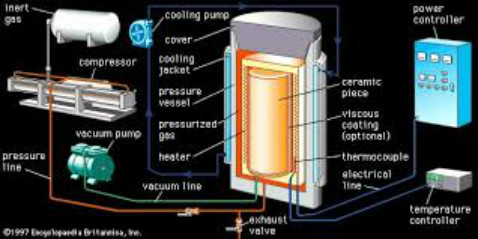

This method uses fluid (water/ oil) as transfer medium to obtain a uniform static pressure on the material. That is, using incompressibility and uniform transmission of liquid medium’s pressure to form the products. The raw material power is encapsulated in a rubber or plastic mold isolated from the fluid. Then immerse the rubber mold in the liquid of pressurized container, like glycerol, oil, water or other non-compressible liquid. Pressure is applied to the rubber mold in all directions by fluid delivery through the high pressure pump. The powder was evenly molded with the deformation of the rubber mold.

Embryo has uniform texture with high density and less defects. The burning shrinkage is at average level with low dry pressure. It can be applied to produce parts with concave, hollow, elongated parts and with other complex shapes. Since there is little friction loss, the pressure can be low and passed from all directions. The embryo has uniform density and high strength with low cost.

Compact size and shape of the compact are not easy to control. The processing is not easy to achieve automation with low productivity.

Isostatic Pressing Machine