- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

As a new material with excellent mechanical, thermal and chemical properties, structural ceramics gradually replaced similar metal materials to make the equipment work in a variety of harsh environments. Zirconia ceramics have been used in many fields due to their excellent mechanical and thermal properties, and thus become a famous representative in the field of structural ceramics.

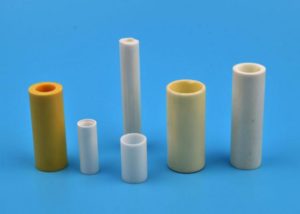

Zirconia ceramic cylinder sleeve and plunger

Zirconia ceramic cylinder sleeve and plunger have the characteristics of wear resistance, corrosion resistance, high-temperature resistance, high strength, high hardness, high life and impact resistance, and are widely used in oil and gas opening equipment such as mud pump, water injection pump, and fracturing pump. Compared with metal material products, its product performance is improved by 8-10 times, which greatly improves oil and gas extraction efficiency and reduces exploitation cost.

Sander fittings

With the wide application of new energy and nano-new materials, the demand for the horizontal sand mill, vertical sand mill, stirring mill and other kinds of ultra-fine grinding equipment is also increasing. Zirconia ceramic accessories are widely used in various industries such as electrode materials, nanomaterials, printing ink, medicine, chemical industry and ceramics because of their advantages such as good performance and less wear.

Wear-resistant ceramic

Zirconia wear-resistant ceramics have the advantages of high hardness, high strength, good wear resistance, long service life and heat resistance, so it can stand various tests in the harsh working environment. Therefore, it is often used in the fields of grinding and polishing materials, wear-resistant coatings, the inner lining of pipes or equipment, and structural parts of equipment. Common zirconia wear-resistant ceramics are the wear-resistant tube, wear-resistant block, lining board, lining brick and lining, etc., and different product types and specifications can be selected according to different equipment and usage conditions.

CZY

The CZY is prepared by isostatic pressure with the materials of micron and subnanometer zirconia and yttrium oxide. Due to its excellent properties such as low wear loss, high density, strong toughness, high hardness, high-temperature resistance, anti-acid, anti-corrosion, and anti-magnetic, it is often used for ultra-fine grinding and dispersion of materials requiring “Zero Pollution” and high viscosity and hardness. CZY is commonly used in electronic ceramics, magnetic materials, zirconia, medicine and food, pigments, dyes, inks, special chemical industries.

Ceramic knife

The ceramic knife is made of nanometer high purity zirconia material, which is called “Artificial Gem”. The sharpness of the ceramic knife with high strength, hardness, corrosion resistance is more than 10 times of steel knife.

Stanford Advanced Materials supplies high-quality zirconia ceramics and related products to meet our customers’ R&D and production needs. Please visit http://www.samaterials.com for more information.