- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

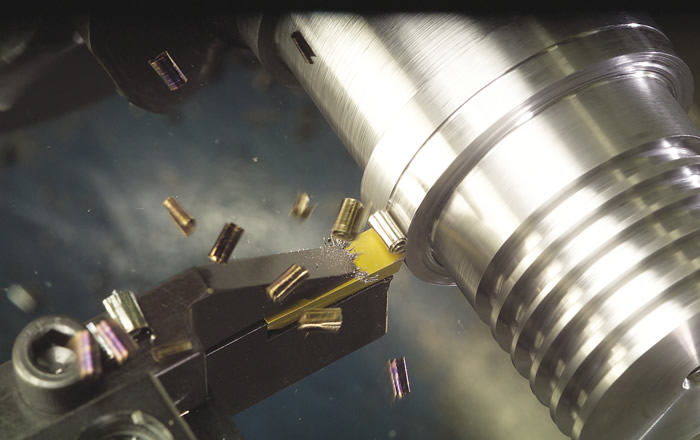

With the development of modern manufacturing technology, traditional carbide cutting tools have been unable to meet the production needs of new and difficult materials. Silicon nitride ceramic cutting tools are favored for their high hardness, strength, good fracture toughness, high-temperature oxidation resistance, and thermal shock resistance, which are widely used in hard cutting, high-speed cutting and so on.

Advantages of silicon nitride ceramic cutting tools

Compared with carbide cutting tools, silicon nitride ceramic cutting tools have obvious advantages, which are shown in the following aspects.

Silicon Nitride Ceramic Cutting Tools

Applications of silicon nitride ceramic cutting tools

Auto parts processing

A series of parts such as milling cylinder cover, cylinder sleeve, and automobile brake disc are processed with composite silicon nitride ceramic blade, which can improve the efficiency. For example, a milling cutter can increase its speed from 92r/min to 275r/min.

Bearing machining

The rolling bearing adopts the technology of rough, fine, quenching, rough grinding, and fine grinding for a long time. For example, after hardening to 63HRC, the blank of GCr15 precision forging bearing will be deformed and uneven and will get stuck in the rough grinding of the automatic grinding machine directly, and even burn the spindle of grinding machine in serious cases. The finishing process of bearing ring before quenching and the rough grinding process after quenching are combined into the finishing process of ceramic cutter after quenching, which will make the workpiece fully meet the required size and geometric accuracy, realize the substitution of grinding by car and greatly improve the processing efficiency.

Hard cast iron processing

If the composite nitride ceramic tool is used to process the cold cast iron roll, the tool life is increased four times than that of cemented carbide; it can be used to process superhard nickel alloy spray welding roller bushing, which can greatly improve the cutting efficiency and speed, save time and cost and improve economic efficiency.

Other fields

In the fields of machinery, metallurgy, mining, railway locomotive, aerospace, precision instruments, molds, etc., the technology can be reformed by using silicon nitride ceramic cutting tools to greatly improve production efficiency, save energy and reduce cost.

Please visit http://www.samaterials.com for more information.