- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

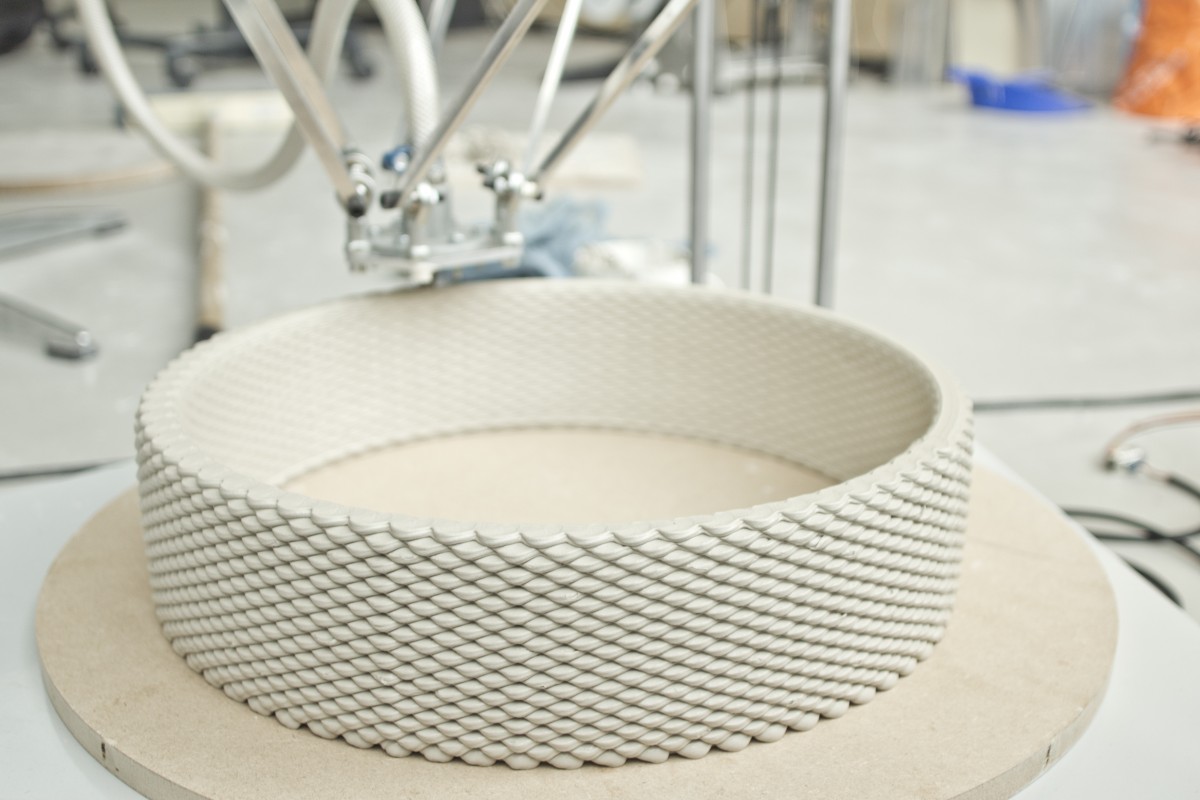

There are many many disadvantages on traditional ceramic manufacturing technology, such as which needs long lead time (at least 8 ~ 12 weeks); not suitable for making complex geometric configurations like hollow sphere. Some special geometric configurations, or some parts of the design often is not suitable for mechanical processing, which needs for a costly follow-up processing methods: certain pattern or model must use expensive carbide or diamond and other tools to processing before and after the ceramic sintering. So small manufacture often need expensive cost and long delivery time.

Ceramic production with the ceramic 3D printing costs 90% less time than the traditional methods, even the time of delivery may within 5 days. The new technology not only saves time, and at the same time also allows designers change their design in the ceramic production process. There are various kinds of ceramic materials can be used in the 3D printing technology, from the alumina ceramic (alumina filler) whose hardness was a little weak to very hard zirconia ceramic (zirconia silicate filler) with wear-resistant .These ceramic can tolerate high temperature of 1500 ~ 1700 degrees, the dielectric strength of which up to 150 kv/mm. The alumina ceramic materials not only has strong wear resistance but also corrosion resistance, and is an ideal mechanical manufacturing raw materials.

High strength and high hardness

Excellent wear resistance

High resistance to corrosion

Excellent thermal stability

Excellent dielectric strength

Used as a nozzle in the high friction environment (such as sandblasting)

Used for air gun protection cover in high temperature environment (such as welding equipment)

Used as a base in corrosive environment (such as car manufacturing tactile sensor installation)

Many parts can be designed for half a hollow structure with the ceramic 3D printing technology, thus the weight reduction and cost savings achieved.

Please visit http://www.samaterials.com for more information.

Do you guys do custom printing of Zirconium oxide ceramics?

We’re looking to create a ceramic nosecone tip for a rocket. It will likely be ogive shaped, no more than 3″ in diameter.

Sorry for the delayed reply, because our editor seldom checks the comments. We do offer custom printing of ceramic materials.

Are you still in need of ceramic materials? If so, you can contact our salespeople via online inquiry form: https://www.speciaLceramicparts.com/inquiry/. They are specialized in customer service and can give you a satisfactory reply.