- Alumina

- Boron Nitride

- Zirconia

- Other Ceramics

- Applications

- Contact

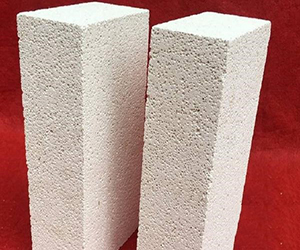

| Catalog No. | AC3491 |

| Material | Al2O3 |

| Purity | 98.8% |

| Size | Customized |

Alumina Bubble Brick contains more than 90% Al2O3 and is a lightweight refractory product mainly composed of corundum. Al2O3 and the appropriate amount of clay and bonding agent are used as raw materials, and gas blowing agents are used in the preparation stage. The product has good high-temperature structural properties and can be used in industrial kilns at 1600~1800°C.

Alumina Bubble Brick contains more than 90% Al2O3 and is a lightweight refractory product mainly composed of corundum. Al2O3 and the appropriate amount of clay and bonding agent are used as raw materials, and gas blowing agents are used in the preparation stage. The product has good high-temperature structural properties and can be used in industrial kilns at 1600~1800°C.

| Properties | SPEC | TYPICAL | |

| Classification temperature (°C) | 1800°C/3270°F | ||

| Bulk Density (g/cm3) | 1.65 Max | 1.55 | |

| Cold Crushing Strength (kg/cm2) | 100 Min | 150 | |

| Thermal Conductivity (W/mK) at 350°C | – | 0.9 | |

| Reheat shrinkage (1,700°C*8 hours, %) | – | 0.06 | |

| Chemical Composition (%) | Al2O3 | 98.0 Min | 99.2 |

| SiO2 | – | 0.3 | |

| Fe2O3 | 0.5 Max | 0.2 | |

Used as the main refractory lining for hot surfaces or as an insulation material behind other refractories in furnaces, flues, kilns and similar high-temperature industrial equipment.

Our Bubble Alumina Bricks are carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Leave a message

—

Please send your request to special.ceramic@made-parts.com , and we will reply you within 3 minutes.